Impact Crusher

Impact crusher is widely used in the production of high grade stone materials used in highway, hydropower, artificial sand and stone, crushing, construction and other industries with its excellent performance.

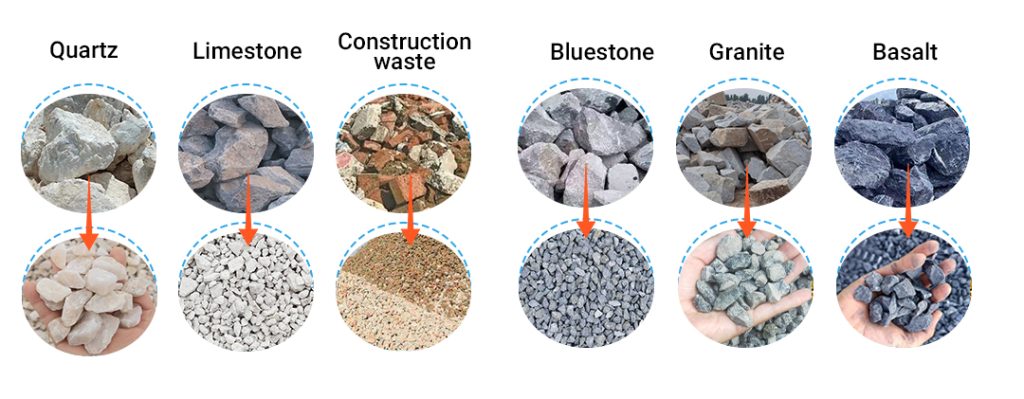

Application

Impact crusher is widely used in many fields:

Sand and gravel production: It is used to produce high-quality mechanism sand and aggregate, providing raw materials for construction, highway, railroad and other infrastructure construction.

Mining: In the process of mining, impact crusher can be used for fine crushing operation to improve the utilization rate and grade of ore.

Solid waste treatment: In the treatment of construction waste and waste concrete, impact crusher can realize the reuse of resources and promote the circular economy.

Features of Impact Crusher

- High-efficiency fine crushing capacity: With its unique impact plate design and high-speed rotor, the impact crusher can quickly crush materials finely, greatly improving production efficiency.

- Excellent particle shape: the material processed by the impact crusher has a cubic particle shape without tension and cracks, which meets the requirements for the production of high-quality sand and gravel aggregates.

- Energy saving and environmental protection: low energy consumption during the operation of the equipment, and the use of advanced dust removal device, effectively reducing dust emissions, to meet environmental standards.

- Easy maintenance: the structure of the impact crusher is reasonably designed, easy to maintain and overhaul, reducing the user’s operating costs.

- Strong adaptability: the machine is able to handle a variety of materials, such as limestone, quartzite, coal gangue, etc., to meet different production requirements.

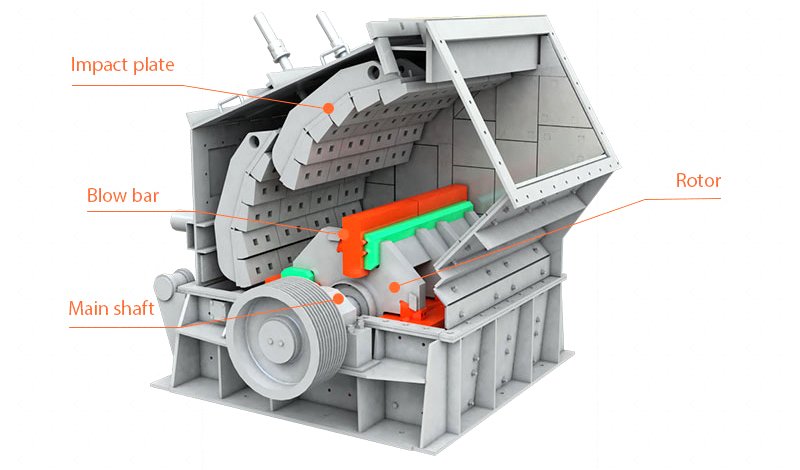

Structure of Impact Crusher

How does a Impact Crusher work?

The working principle of Impact Crusher is to use the high-speed rotor to throw the material to the impact plate, and the material is crushed in the process of impact. After crushing, the materials are bounced and hit many times in the machine, and gradually crushed to the required size, and finally discharged from the discharge port. This working principle ensures the high efficient fine crushing capacity and excellent particle shape of the impact crusher.

Customer Site

Specification

Impact Crusher

| Model | Specification(mm) | Feed Opening(mm) | The Maximum Feeding Size(mm) | Capacity (t/h) | Power(kw) | Overall Dimension (mm) | Total Weight(t) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 | 12 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 | 15 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 | 17.7 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 | 22.4 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 | 27 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 | 34 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 | 50.6 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 4400×3866×4009 | 83.21 |

Zoneding Machine

Zoneding Machine