Compound Crusher

A compound crusher, also called vertical compound sand maker, is a double-rotor primary impact crusher. The compound crusher is an ideal machine for crushing high-moisture and viscous materials, commonly used in small-scale crushing and sand production lines.

Features of Compound Crusher

- High-efficiency crushing: Adopting special crushing chamber design and high-speed rotor, it can quickly and effectively crush all kinds of materials and improve production efficiency.

- Wide applicability: not limited by material humidity, viscosity, etc., it can handle a wide range of hardness of ores, rocks and construction materials.

- Energy saving and environmental protection: optimized power system and low energy consumption design reduce energy consumption, while low noise operation reduces the impact on the environment.

- Easy maintenance: simple structural design and high-quality wear-resistant materials reduce maintenance costs and extend the service life of the equipment.

- Intelligent control: optional automation control system can monitor the running status of the equipment in real time, ensuring the stability and safety of the production process.

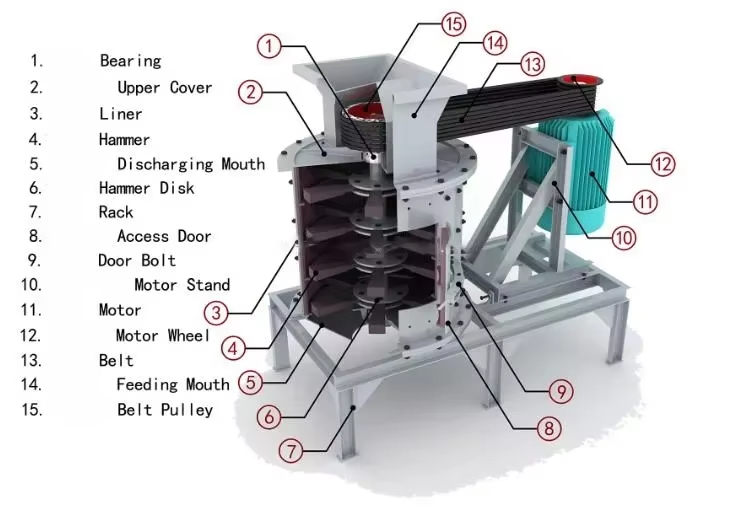

Compound crusher structure

The vertical compound crusher is mainly composed of the crushing system (rotor, bearing, liner, hammer), transmission system (motor, pulley), in-and-out mouths, and other parts.

How does a Features of Compound Crusher work?

The working principle of the compound crusher is that the material from the upper part of the machine falls vertically into the high-speed rotating impeller, under the action of high-speed centrifugal force, and the other part of the umbrella-type way of diversion in the impeller around the material to produce high-speed impact and crushing, the material in each other after the impact and will be between the impeller and the casing with the material to form a vortex for many times of each other’s impacts, friction and crushing, from the lower part of the straight-through discharge to form a closed-circuit cycle for many times, and the material is controlled by screening equipment to achieve the required finished product size. It is controlled by the screening equipment to reach the required particle size of the finished product. This type of crushing combines the advantages of impact type and counterattack type, and is characterized by large crushing ratio, low energy consumption, stable operation, even and adjustable granularity of the discharged material.

Application

Compound crusher is widely used in many industries, including but not limited to:

- Mining: used for crushing various ores to improve beneficiation efficiency and ore utilization.

- Building materials: to produce building aggregates, such as sand and stone.

- Metallurgical industry: pre-treatment of metal ores to facilitate the subsequent smelting process.

- Chemical industry: crushing chemical raw materials for further chemical reaction or extraction.

- Environmental protection and resource recycling: processing construction waste, waste residue, etc. to realize the reuse of resources.

Specification

Compound Crusher

| Specification | Processing Capacity(t/h) | Motor Power(kw) |

| 800 | 5-15 | 4p 30kw |

| 1000 | 10-30 | 4p 55kw |

| 1250 | 20-60 | 6p 90kw |

| 1500 | 30-80 | 8p 110kw |

| 1750 | 40-100 | 8p 160kw |

Zoneding Machine

Zoneding Machine