Conveyor Belt

Conveyor belt is also called rubber conveyor belt, which relies on the friction between the roller and the conveyor belt to continuously transport materials.

Features and Technology Advantages of Belt Conveyor

- High efficiency and stability: advanced drive system and high quality materials are used to ensure that the conveyor belt remains stable at high speeds, greatly improving productivity.

- Strong durability: Made of wear-resistant and corrosion-resistant materials, it is durable and reduces the frequency of repairs and replacements, lowering maintenance costs.

- Flexible and versatile: length, width and speed can be customized according to different production environments and needs, as well as adding various attachments, such as side baffles and guide strips.

- Energy-saving and environmental protection: Optimized design and energy-saving motors reduce energy consumption and carbon emissions, in line with the modern green production concept.

- Safe and Reliable: Equipped with multiple safety guards, such as anti-skid, anti-runout, emergency stop, etc., to ensure the safety of operators.

How does a Features of Conveyor Belt work?

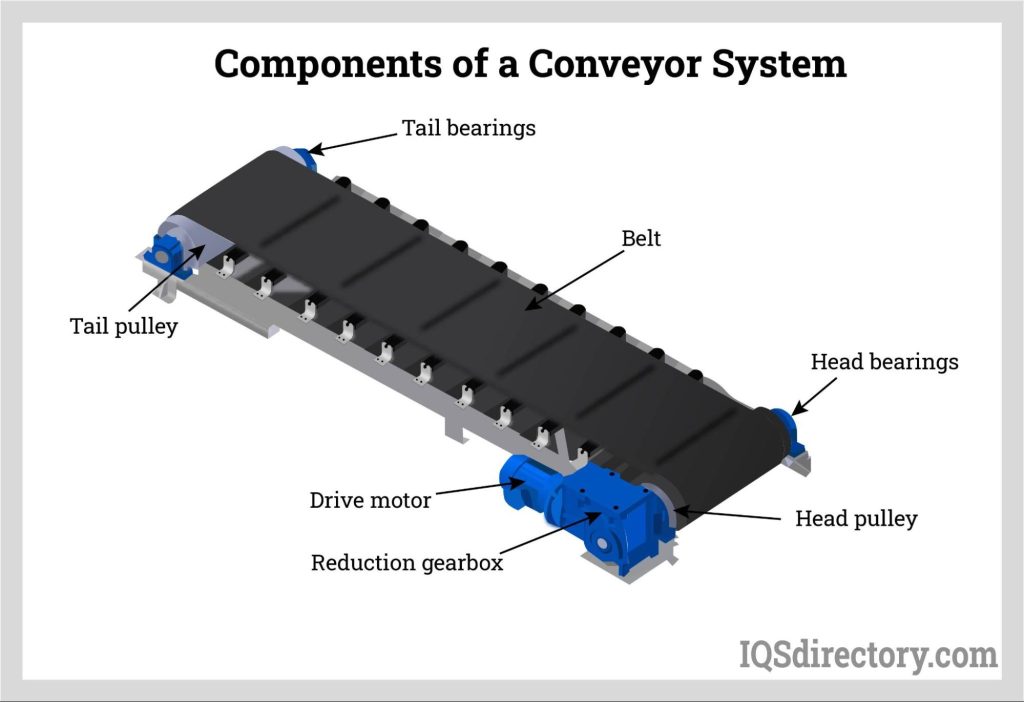

Conveyor belts are mainly composed of a driving device, a conveyor belt, a support structure and a tensioning device. When the driving device starts, the conveyor belt is driven to move by friction. The material is placed on the conveyor belt and moves forward with the movement of the conveyor belt. The support structure ensures the stability and flatness of the conveyor belt, while the tensioning device maintains the proper tension of the conveyor belt to prevent it from running off or slackening. The whole system works together to realize efficient and continuous conveying of materials.

Application

Our conveyor belts are widely used in a number of industries, including but not limited to:

- Logistics & Warehousing: for rapid sorting and transportation of goods.

- Mining: conveying various ores and coal.

- Food Processing: Hygienic grade conveyor belts to ensure cleanliness and safety of food products.

- Pharmaceutical industry: GMP compliant conveyor belts for the production and packaging of pharmaceuticals.

- Electronics industry: precision conveyor systems for assembly and inspection of small parts.

Customer Site

Specification

belt conveyor

| Belt width(mm) | Conveying length(m) Power(kw) | Conveying speed(m/s) | Conveying amount(t/h) | ||

| 400 | ≤103 | 12-153-4 | 15-304-7.5 | 1.25-2.0 | 30-60 |

| 500 | ≤103 | 12-154-5.5 | 15-305.5-7.5 | 1.25-2.0 | 40-80 |

| 650 | ≤104 | 12-157.5 | 15-307.5-11 | 1.25-2.0 | 80-120 |

| 800 | ≤104 | 12-157.5 | 15-307.5-15 | 1.25-2.0 | 120-200 |

| 1000 | ≤105.5 | 10-207.5-11 | 20-4011-22 | 1.25-2.0 | 200-320 |

| 1200 | ≤107.5 | 10-207.5-15 | 20-4015-30 | 1.25-2.0 | 290-480 |

| 1400 | ≤1011 | 10-2015-22 | 20-4022-45 | 1.25-2.0 | 400-680 |

| 1600 | ≤1015 | 10-2022-30 | 20-5030-75 | 1.25-2.0 | 600-1080 |

| 1800 | ≤1018.5 | 10-2030-45 | 20-5045-110 | 1.0-2.0 | 800-1500 |

| 2000 | ≤1022 | 10-2045-55 | 20-5055-132 | 1.0-2.0 | 1000-2000 |

| 2400 | ≤1030 | 10-2055-75 | 20-5075-185 | 1.0-2.0 | 1500-3000 |

Zoneding Machine

Zoneding Machine