Magnetic Separator

In mineral processing, a magnetic drum separator, also known as a drum magnet, separates non-magnetic material from magnetic material by using magnetic differences.

Types of magnetic drum separators

Magnetic drum separators are divided into dry magnetic drum separators and wet magnetic drum separators.

Features of Magnetic Separator

- High-efficiency separation: the magnetic separator adopts high-performance magnetic system with high magnetic field strength and good separation effect, which can quickly and accurately separate the magnetic substances in the materials.

- Energy-saving and environmental protection: the equipment adopts energy-saving design to reduce energy consumption, and at the same time reduces noise and dust emissions, in line with environmental requirements.

- Stable and reliable: the magnetic separator has a solid structure, stable operation and durability, which reduces the failure rate and maintenance costs.

- Easy to operate: the equipment adopts humanized design, easy to understand the operation, reduce the difficulty of operation and improve work efficiency.

- Strong adaptability: the magnetic separator can be adapted to the magnetic separation needs of a variety of materials, widely used in different industrial fields.

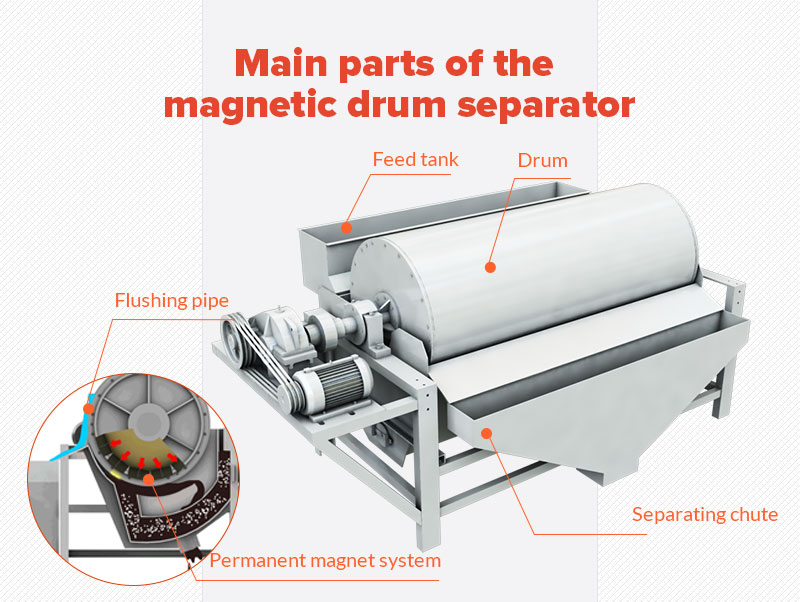

Structure of Magnetic Separator

Magnetic Separators typically consist of a magnetic drum, transmission system, tank, feeding device, and discharge device. The magnetic drum, a crucial component, is equipped with high-performance permanent magnets or electromagnets that generate a powerful magnetic field. The tank holds the pulp, while the feeding device evenly distributes the pulp into the magnetic separator. The discharge device is responsible for removing the separated minerals.

How does a Features of Magnetic Separator work?

The working principle of the magnetic separator is based on the different magnetic manifestations of magnetic and non-magnetic substances in the material in the magnetic field. When the material passes through the magnetic field area of the magnetic separator, the magnetic material is attracted by the magnetic field and attached to the magnetic system of the magnetic separator, while the non-magnetic material continues to flow. Subsequently, the magnetic substances are separated from the magnetic system by appropriate mechanical devices, thus realizing the separation of magnetic and non-magnetic substances in the materials.

Application

Magnetic separator is widely used in the following fields:

Customer Site

Specification

Magnetic Separator

| Model | Shell diameter (mm) | Shell lenght (mm) | Shell rotation speed(r/min) | Feeding size (mm) | Processing capacoty (t/h) | Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

Zoneding Machine

Zoneding Machine