Coal Dryer

Zoneding’s coal dryer is designed to handle high-humidity coal, suitable for various coal particles. It efficiently smashes and dries coal, making it a versatile source for power plants and industrial raw materials, with applications in construction, metallurgy, and mining.

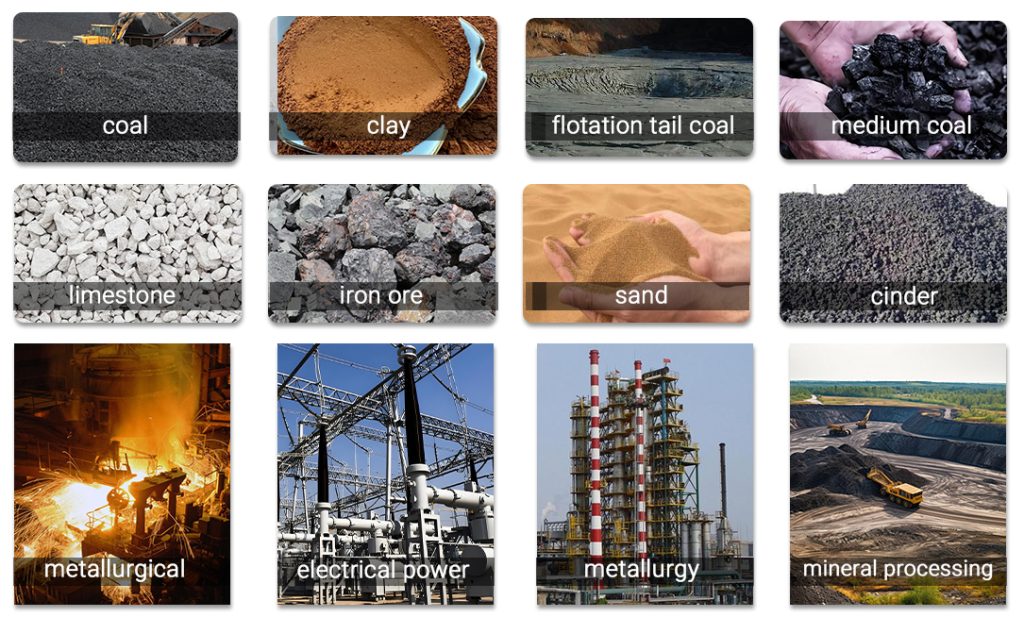

Coal Dryer Application

The rotary coal dryer is mainly used for drying coal materials with high water content, fine particle size and high viscosity (slime, flotation tail coal, mixed coal, pressure filtration tail coal, final clean coal, medium coal, or concentrate powder). It can also be applied for drying building materials, mines, clay, sand, limestone, chemical industry, metallurgy, electric power and other industries.

Features of Coal Drying Machine

1. Good drying effect, uniform drying degree

2. Large processing capacity, high work efficiency

3. Energy saving, environmental protection, less fuel consumption

4. Compact structure, simple operation

5. Meet the production needs of different users.

Working Principle of Coal Dryer Machine

Wet coal of a certain humidity firstly passes through a professionally designed dispersion device. The well-dispersed coal is conveyed to the feeder, by which it is then fed into the cylinder. Here in the rolling drum, wet coal is thrown up and down by blades and gets water and heat exchanged. The dried coal is belched out of the drum by the star-shaped unloader and conveyed to the package. The entire drying process is completed.

Advantages of Rotary Coal Dryer

1.Strong overload resistance, large processing capacity, low fuel consumption and low drying cost.

2.The operating parameters can be changed according to the properties of different materials.

3.Adopt new feeding and discharging device, avoid feeding blockage, discontinuity, unevenness and returning of the rotary dryer, and reduces the load of the dust removal system.

4.Particle size and moisture can be controlled according to user requirements. When drying coal slime, the product moisture can reach below 8%, and the particle size can be controlled below 8mm.

Customer site

Specification

Coal dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Zoneding Machine

Zoneding Machine