Crop Straw Dryer

The straw dryer is a new type of agricultural drying equipment developed for the reuse of crop stalk, which is widely used for drying agricultural cellulose materials. The straw drying machine has fast drying speed, high drying intensity, full-automatic control and stable and reliable operation. The dried crop straws can be used as feed for animals, and can also be used to make biomass pellets or produce various straw products.

Crop Straw Dryer

Advantages of Crop Straw Dryer

1.Simple structure, less faults, low maintenance cost, large production capacity and long-term continuous operation.

2.Multiple heat sources can be selected, biomass, biogas, steam, coal, electricity, etc.

3.Equipped with temperature measurement sensor and digital display instrument, realize the drying effect and ensure the safe operation of the drying system.

4. Unique sealing device and the effective thermal insulation system are adopted to reduce the coal consumption of the drying system effectively.

Crop Stalk Drying Machine Application

Our crop straw dryer is widely used for drying agricultural cellulose materials such as corn straw, soybean straw, cotton stalk, wheat straw, sorghum straw, mulberry leaf, etc. It can also be used for spent grain, forage, apple residue, soybean residue, compound fertilizer and other materials.

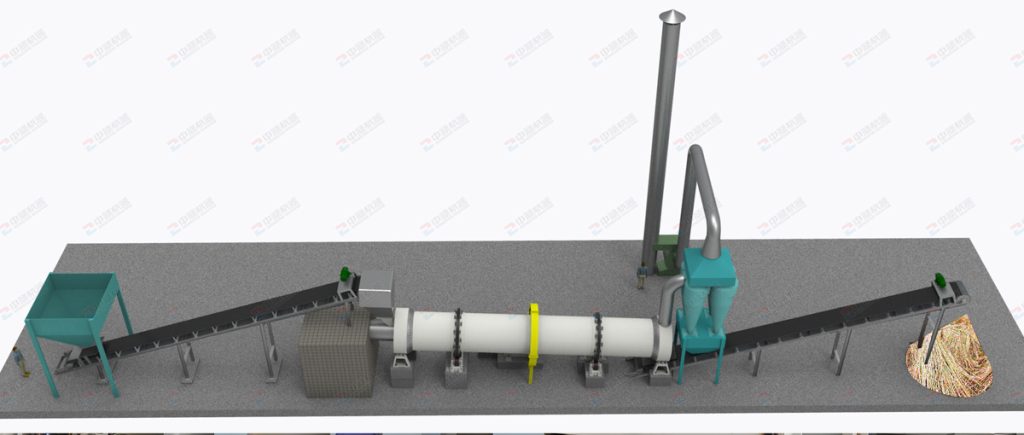

Crop straw dryer workflow

The straw drying production line includes combustion furnaces, feeders, conveyors, dryers, motors, reducers, dust collectors, forced draft fans, etc. The high-temperature flue gas generated by the heat source enters the dryer under the action of the backdraft fan and is in contact with the straw to transfer the heat. After the water evaporates, it is directly drawn into the dust collector and the straw is dried. Once it is still in the dryer, it does not fall out of the cutting hole until it reaches the set humidity.

Specification

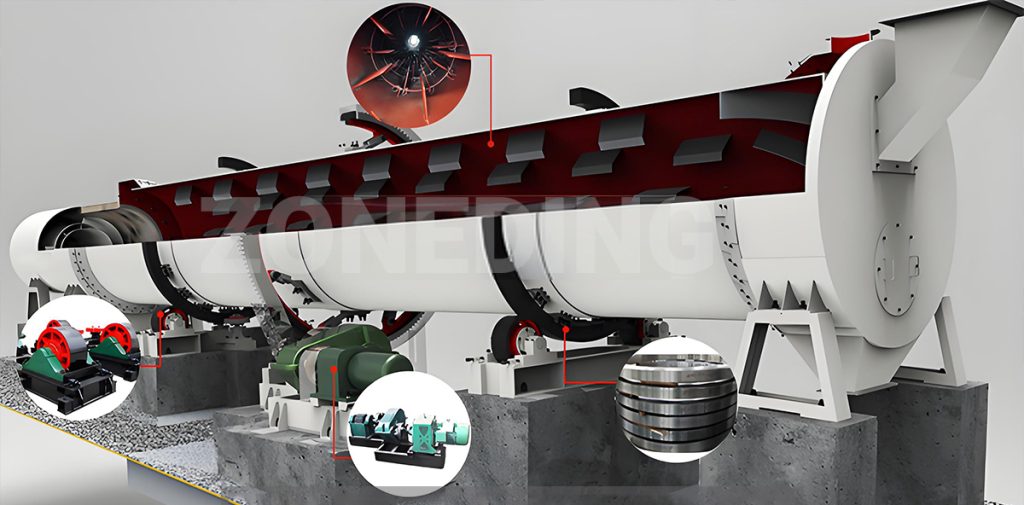

Drum Dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Zoneding Machine

Zoneding Machine