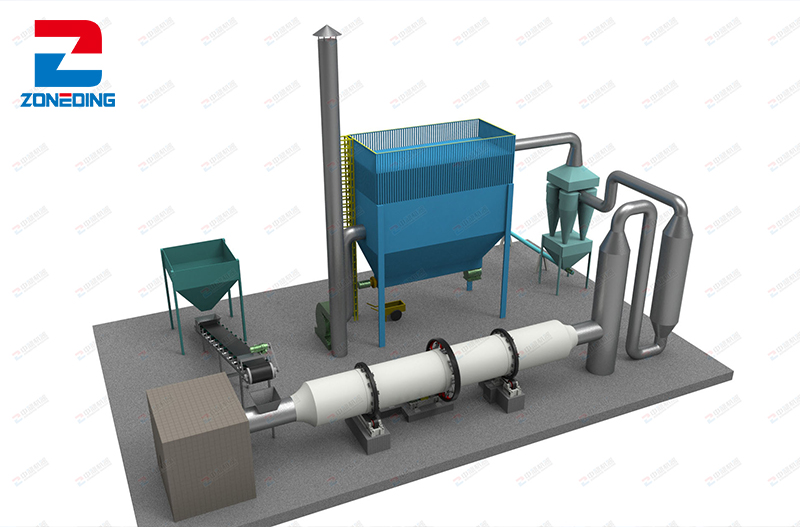

Bentonite Dryer

Bentonite clay is a non-metallic mineral with montmorillonite as the main mineral component. After drying, it can be used in agriculture, light industry, cosmetics and pharmaceuticals industries. The bentonite drying machine is a kind of drying equipment for bentonite minerals, which has the advantages of large drying capacity, low drying cost, fast drying speed, simple and easy operation. In the drying process, the hot air flow is in full contact with bentonite clay, with high drying temperature and high drying intensity, the water is continuously evaporated in the cylinder.

Bentonite Dryer

Applications of Bentonite Dryer

Through the drying treatment with bentonite drying equipment, the moisture content of bentonite can be reduced, thereby enhancing its stability and plasticity, making it more suitable for various industrial and agricultural applications. Bentonite exhibits excellent characteristics such as adsorption, gelling, and swelling. After bentonite drying, bentonite can be utilized as a binder, suspending agent, stabilizer, purifying and decolorizing agent, filling material, feed additive, catalyst, etc., and is widely employed in fields such as petroleum extraction, steel and iron casting, metallurgical pelletizing, chemical coatings, compound fertilizers, papermaking, water purification, pesticides, etc.

Advantages of Bentonite Dryer

1. Reasonable structure

Simple design, small floor area, easy construction and maintenance, economical and convenient.

2. High drying efficiency

The sealing structure can not only effectively ensure the air induction effect, but also prevent the entry of cold air, and greatly improve the drying efficiency.

3. High thermal efficiency

Equipped with high-yield radiator and reasonable air duct, it can greatly improve the contact area between materials and hot air, greatly improve thermal efficiency and effectively save energy.

4. High automation degree

The bentonite dryer adopts computer automatic control to realize drying automation.

How Bentonite Dryer Works

When bentonite drying machine is operated, the law of heat transformation and the effect of gravity play the main role. The drum is set at an angle of about 3-5。. Wet bentonite is conveyed into the higher end of the cylinder by feeding system and falls down into a screen, which favors the efficiency of heat transformation. When the drum rotating, bentonite is raised by the blades and falls. Here heat transformation between scorching wind and wet materials works best. Under the gravity, dried bentonite steps down to the lower end of the drum and is blenched out. In the gradual stepping down, the excessive liquid is removed. There equips a professional dust collector to collect waste gas.

Specification

Bentonite dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Durable Machinery

Durable Machinery