Ceramic Ball Mill

Ceramic ball mill, as a grinding tool for modern refinement industry, stands out in many industries with its unique material and efficient grinding performance. The machine adopts high-quality ceramic material to make grinding media, which ensures stable grinding effect in high-speed operation and avoids metal contamination at the same time, which is the first choice of equipment for pursuing high purity grinding effect.

Advantages of Ceramic ball mill

- High purity grinding: using ceramic balls as grinding media effectively avoids the pollution of metal ions on the materials, ensuring the high purity of the materials after grinding.

- High-efficiency grinding: optimized structural design makes the ceramic balls form a reasonable movement trajectory inside the mill, which improves the grinding efficiency and shortens the processing time.

- Energy saving and environmental protection: adopting advanced energy-saving technology to reduce energy consumption, and low noise design to create a comfortable working environment.

- Easy maintenance: simple structure design makes the daily maintenance and upkeep of the equipment simple and easy.

- Widely used: suitable for ceramics, chemical, pharmaceutical, food and many other industries to meet the grinding needs of different materials.

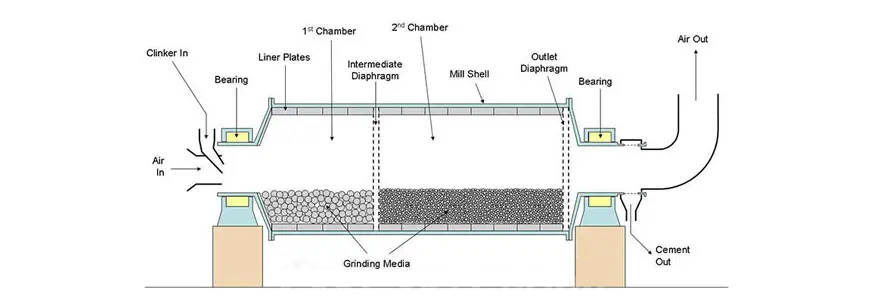

Working principle of ceramic ball mill

The motor on the ceramic ball mill drives the cylinder to rotate through the deceleration device, and then the crushed ore and the grinding balls in the cylinder are brought to a certain height by the lining plate due to the friction and centrifugal force when the cylinder rotates, and then fall and fall due to gravity. Falling, the ore is gradually crushed under the action of impact and grinding. The crushed ore is discharged out of the barrel through the discharge part. After the discharged minerals are classified into qualified products in the spiral classifier, the coarse sand passes through the combined feeder and returns to the ball mill to continue grinding. The feeder feeds continuously and evenly, the ore enters the ceramic ball mill machine continuously and uniformly through the combined feeder, and the ground materials are continuously discharged from the ceramic ball mill. Ceramic ball mill equipment is a grinding equipment that can work continuously 24 hours a day.

Application Scenarios of Ceramic ball mill

Whether it is glaze preparation in the ceramic industry, powder mixing in the chemical industry, or drug grinding in the pharmaceutical industry, the ceramic ball mill can meet your grinding needs with its excellent performance. It is widely used in various scenarios that require high purity and high precision grinding, and is a powerful assistant to improve product quality and productivity.

Ceramic Ball Mill Specifications

Ceramic ball mill customer work site

Parameter

Ceramic Ball Mill

| Model | Feeding capacity (t/time) | Shell rotation speed (r/min) | Reference motor (kw) | Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

Zoneding Machine

Zoneding Machine