Cocopeat Dryer

Cocopeat (coconut coir) is the powdery substance between coconut husk fibers. After drying, the coconut peat can be used in the field of plant cultivation or making into coconut bricks, which has high economic benefits.

Advantages of Coconut Coir Dryer Machine

* Intelligent control, one-key operation, automatic control of operating parameters.

* The temperature is precisely controlled to keep the material temperature below 50℃, and the dried coconut coir completely retains its original color and fragrant smell.

* A variety of high-efficiency lifting plates combination modes is adopted to effectively control the drying process and heat distribution, with high heat utilization rate and low exhaust gas discharge temperature.

* Three levels of dust removal equipment can be configured as required.

* Adopt energy-saving clean hot air stove, and the fuel can be fuel oil, gas, coal, biomass energy, etc.

Wide Application of Cocopeat after Drying

Our coco peat rotary dryer can be used for drying cocopeat, coconut coir, coconut fiber, palm fiber, etc. It is also applied for wood chips, wood shavings, sawdust, and other biomass materials.

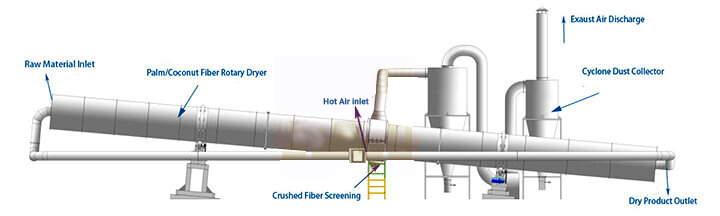

Structure of Cocopeat Dryer

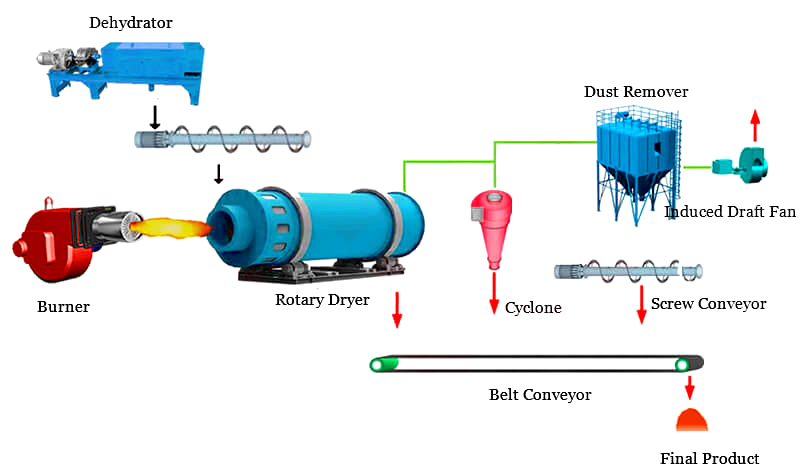

Coconut coir dryer production line is composed of hot air stove, rotary dryer, feeder, conveyor, dust remover, packer and other related supporting equipment. The specification, model, material and configuration of the equipment are specially designed according to the specific requirements of customers.

Cocopeat Drying Machine Working Principle

After the desalination and dehydration, the cocopeat bran with the moisture content of 50-60% is delivered to the drum by the conveyor to realize the downstream drying. The coconut coir is continuously lifted and scattered in a spiral way under the action of lifting boards. The heat exchange between coconut bran and hot air is realized through the inner, middle and outer layers. The coconut bran that has reached the drying effect is discharged from the drum under the action of wind quickly. The coconut bran that has not reached the drying effect cannot move quickly because of its own weight. It will be fully dried in the drum until it reaches the drying effect. Then the coconut coir is discharged by the screw conveyor, thus completing the drying process. Special devices are installed inside the drum to prevent uneven drying of coconut bran.

Specification

Drum Dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Durable Machinery

Durable Machinery