Fine Crusher

The fine crusher is mainly suitable for grinding and processing in metallurgy, building materials, chemical, mining, railway, water conservancy and other industries. It is used before the ball mill to increase the production efficiency of the ball mill by 50%.

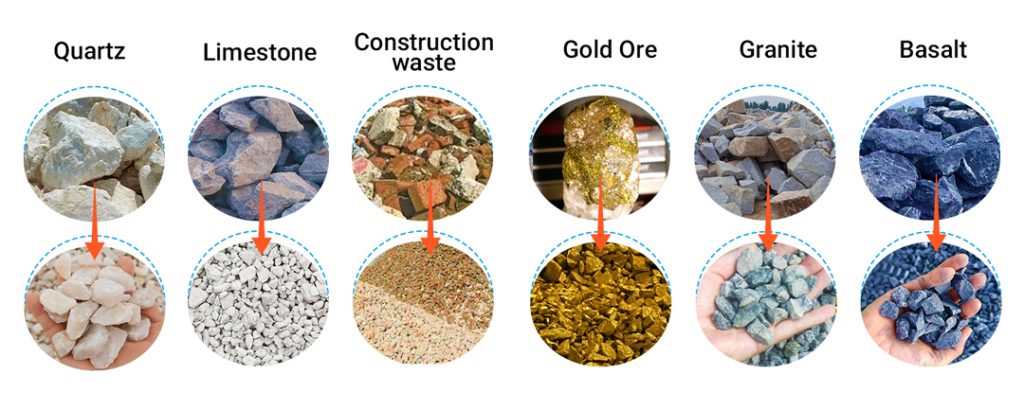

Applications of fine crusher

It is especially suitable for fine and medium crushing of materials with hardness below 9 such as quartz, feldspar, calcite, marble, ceramics, iron ore, copper ore, gangue, phosphate rock, granite, basalt, silicon carbide, corundum, insulation materials and other brittle materials.

Features of Fine Crusher

- High-efficiency crushing: The fine crusher adopts high-speed rotating crushing hammer head, which strongly impacts and shears the materials to realize high-efficiency crushing. Meanwhile, the optimized crushing chamber design ensures that the materials are fully subjected to the crushing force during the crushing process and improves the crushing efficiency.

- Adjustable granularity: By adjusting the gap between the crushing hammer head and screen, the granularity of the crushed material can be easily controlled to meet different production requirements.

- Wear-resistant and durable: the key components of the machine are made of high-strength wear-resistant materials to ensure that the equipment can still maintain excellent performance under long-time operation.

- Energy-saving and environmental protection: The fine crusher adopts advanced sealing design and dust removal device, which effectively reduces dust emission and meets the requirements of environmental protection. Meanwhile, the optimized power system and energy-saving design reduce energy consumption and realize green production.

- Easy to operate: The machine adopts intelligent control system to realize automatic operation, reduce manual intervention and improve production efficiency. Meanwhile, the equipment is easy to maintain, with a long maintenance cycle, reducing operating costs.

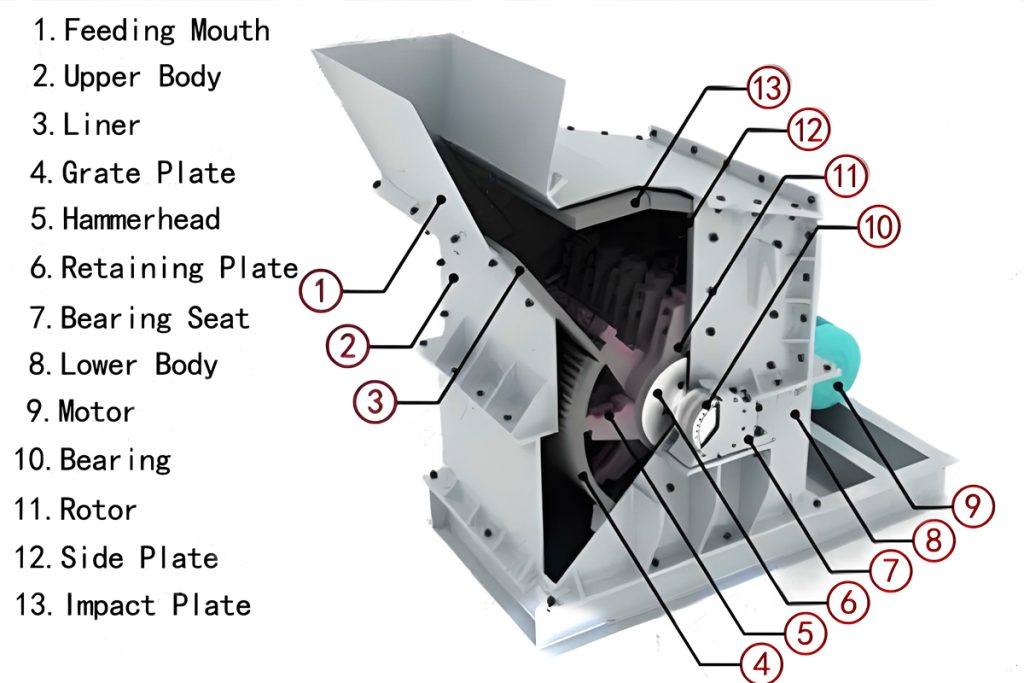

Fine Crusher Structure

How does a Features of Fine Crusher work?

The working principle of the fine crusher is mainly based on the impact and shear of the high-speed rotating crushing hammer head on the material. After entering the crushing cavity from the feed opening, the material is subjected to the strong impact and shear effect of the crushing hammer head, and is quickly crushed into small pieces. After crushing, the materials will be impacted and rubbed many times in the crushing chamber, and gradually reach the required size. Finally, it is discharged from the crushing chamber through the screen, completing the whole crushing process.

Customer Site

Specification

Fine crusher

| PXJ tertiary impact crusher | Rotorø×Width (mm) | |||||||

| Specification | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Feed opening size(mm) | 400×185 | 500×250 | 550×300 | 1000×350 | 1200×450 | 1500 | 1600×550 | 1800×800 |

| Feeding size (mm) | <120 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

| Discharging size (mm) | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

| Adjustable range of discharge opening (mm) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Cement Clinker(t/h) | 10-30 | 1040 | 20-45 | 25-55 | 35-90 | 50-150 | 85-210 | 125-270 |

| Limestone(t/h) | 18-45 | 23-55 | 28-65 | 35-75 | 45-110 | 50-150 | 95-260 | 140-310 |

| Power(kw) | 4P 37KW | 4P 45KW | 4P 45KW | 4P 55KW | 6P 110KW | 6P 160KW | 4P 250KW | 4P 315KW |

| Theoretical weight | 3.9 | 4.5 | 6 | 10.5 | 14.4 | 22 | 35 | 49.7 |

Zoneding Machine

Zoneding Machine