Flotation Machine For Sale

Flotation cell machine is a mechanical device that realizes the foam flotation process and separates the target minerals from the ore. Flotation is a mineral processing method that separates the complex composition of minerals. Flotation machine can be used for many ore beneficiation . It is subject to coarse separation, swept separation, fine separation and flotation, so the useful ore are reclaimed.

Features of Flotation Machine

- High-efficiency separation: unique flotation tank design and bubble generation system are adopted to ensure full contact between minerals and bubbles and improve separation efficiency.

- Energy-saving and environmental protection: optimize the equipment structure and process parameters to reduce energy consumption, and at the same time reduce the discharge of waste water and waste residue, in line with the requirements of green production.

- Simple operation: intelligent control system makes the operation more simple and convenient, reduces manual intervention and lowers the operation cost.

- Stable and reliable: the equipment structure is sturdy, wear-resistant and durable, with low maintenance cost and stable and reliable long-term operation.

- Wide range of application: it is suitable for flotation operation of many kinds of ores and materials, meeting the production requirements of different industries.

Flotation machine application materials

- Mining industry: used in the flotation operation of copper, iron, zinc, lead and other ores to improve the ore grade and recovery rate.

- Metallurgical industry: In the process of metal smelting, it is used to separate metal and non-metal impurities and improve the quality of metal.

- Chemical industry: in the process of extraction and separation of chemical raw materials, to realize efficient and environmentally friendly separation operations.

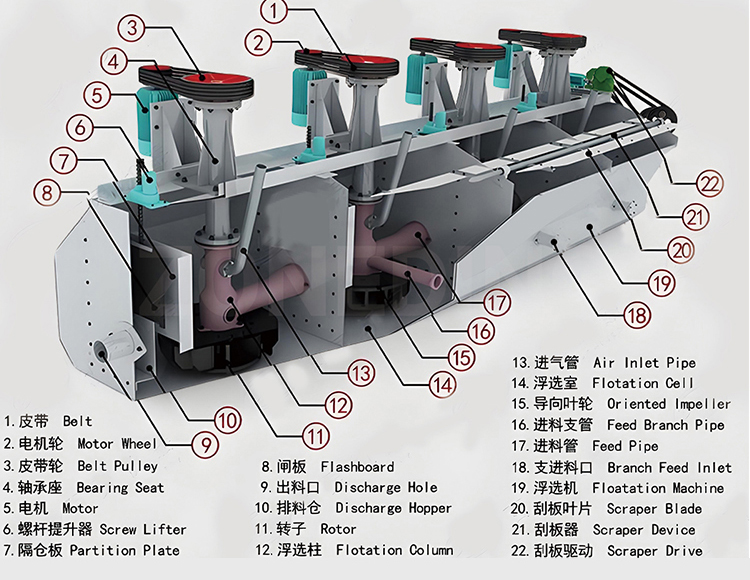

Structure Of Flotation Machine

Flotation machine is mainly composed of impeller, cover plate, vertical shaft, inlet pipe, bearings, belts and other accessories, the wear parts of the equipment are selected from international new wear-resistant and pressure-resistant raw materials, which reduces the wear and tear and prolongs the service life of the equipment.

How does a Features of Flotation Machine work?

The working principle of the flotation machine is based on the differences in physical and chemical properties of mineral surfaces. When the mineral particles are in contact with the air bubbles, due to the different hydrophilicity or hydrophobicity of the mineral surfaces, some of the mineral particles will attach to the air bubbles and float up to the liquid surface with the air bubbles, forming a foam layer. Through the scraper and other devices to scrape out the foam layer, to realize the separation of useful minerals and veins.

In the flotation process, flotation chemicals play a key role. By adding the appropriate amount of trapping agent, foaming agent, etc., to improve the wettability of the mineral surface, and improve the ability of the mineral particles to adhere to the air bubbles. At the same time, adjust the pulp concentration, pH value and other process parameters to optimize the flotation effect.

In addition, the design of the flotation machine also gives full consideration to the flow field distribution and the uniformity of the bubble generation system. By reasonably arranging the air inlet and stirring device, it ensures that the slurry flows evenly in the flotation tank, and the bubbles are uniform in size and distribution, thus improving the flotation efficiency.

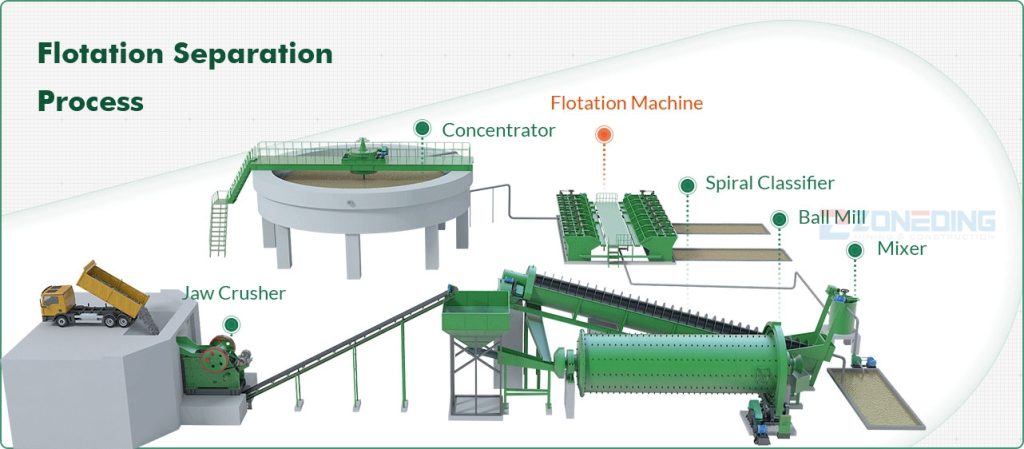

Flotation Process

Flotation process refers to the method used in the flotation process of a mineral. Flotation is the same as other mineral processing methods, to do a good job of material preparation before selection, that is, the ore should be milled and graded to achieve the concentration of fineness suitable for flotation. In addition, flotation has the following basic operations: slurry adjustment and add flotation chemicals, change the mineral wettability so that mineral particles attached to the bubble. Mineralization of bubbles. Selective attachment of mineral particles to air bubbles is the basic behavior of the flotation process. Flotation is a beneficiation method based on the different wettability of minerals by water. Generally, the nature of minerals easy to float and difficult to float is called the floatability of minerals. Flotation is the use of the difference in the floatability of minerals to separate minerals.

Customer site

Specification

Flotation Machine

| Category | Specification Model | Effective cubage (m) | Processing capacity (m/min) | Main shaft loam board | Dimensions (m) | Single trough Weight (t) | |||

| XJK type flotation machine | XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | 0.7x0.7x0.7 | 0.5 |

| XJK-0.62 | 0.62 | 0.3-0.9 | 3.0 | 400 | 25 | 1.1 | 0.90x0.82x0.85 | 1.0 | |

| XJK-1.1 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1x1.1x1 | 1.4 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | 1.75x1.6x1.1 | 2.5 | |

| XJK-5.8 | 5.8 | 5-7 | 22 | 240 | 25 | 1.5 | 2.2x2.2x1.2 | 3.6 | |

| SF type flotation machine | SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | 0.7x0.7x0.75 | 0.5 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9x0.82x0.95 | 1.0 | |

| SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1x1.1x1.1 | 1.9 | |

| SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1.75x1.6x1.15 | 2.6 | |

| SF-4 | 4 | 2-4 | 15 | 220 | 25 | 1.5 | 1.85x2.05x1.2 | 2.9 | |

| SF-8 | 8 | 4-8 | 30 | 191 | 25 | 1.5 | 2.2x2.9x1.4 | 4.2 | |

| SF-10 | 10 | 5-10 | 30 | 191 | 25 | 1.5 | 2.2x2.9x1.7 | 4.5 | |

| SF-20 | 20 | 5-20 | 30×2 | 191 | 25 | 1.5 | 2.85x3.8x2 | 9.9 | |

| JJF type flotation machine | JJF-2 | 2 | 1-3 | 7.5 | 443 | 25 | 1.5 | 1.4x1.4x1.1 | 1.7 |

| JJF-4 | 4 | 2-4 | 11 | 305 | 25 | 1.5 | 1.6x2.15x1.25 | 2.4 | |

| JJF-8 | 8 | 4-8 | 22 | 233 | 25 | 1.5 | 2.2x2.9x1.4 | 4.5 | |

| JJF-10 | 10 | 5-10 | 22 | 233 | 25 | 1.5 | 2.2x2.9x1.7 | 4.9 | |

| JJF-16 | 16 | 5-16 | 30 | 180 | 25 | 1.5 | 2.85x3.8x1.7 | 8.0 | |

| JJF-20 | 20 | 5-20 | 37 | 180 | 25 | 1.5 | 2.9x3.8x2.0 | 10.5 | |

Durable Machinery

Durable Machinery