High Efficiency Concentrator

The high efficiency concentrator is mainly used for dewatering

flotation concentrate and tailings in dressing plants, and also for concentration and purification of liquid containing solid particles in metallurgy, chemical industry, coal, building materials and sewage treatment industries.

Features of High Efficiency Concentrator

- High-efficiency concentration: Adopting unique concentration technology, it can quickly and effectively concentrate the solid particles in the liquid, greatly improving the production efficiency.

- Energy saving and environmental protection: low energy consumption and low noise during the operation of the equipment meet the requirements of modern industry for environmental protection and energy saving.

- Stable and reliable: sturdy structure, stable operation, able to work continuously for a long time, reducing the failure rate and ensuring stable production.

- Easy to operate: intelligent control system makes the operation more simple and intuitive, and reduces the labor cost.

Working principle of high efficiency concentrator

High-efficiency thickener, through the special structure inside, makes the liquid form a circulating flow inside the equipment, and gradually removes the water in the liquid through evaporation, condensation and other physical processes, so as to realize solid-liquid separation. At the same time, the equipment is equipped with advanced control system, which can adjust the concentration speed and concentration according to different material characteristics and production requirements to achieve the best concentration effect.

High efficiency concentrator structure

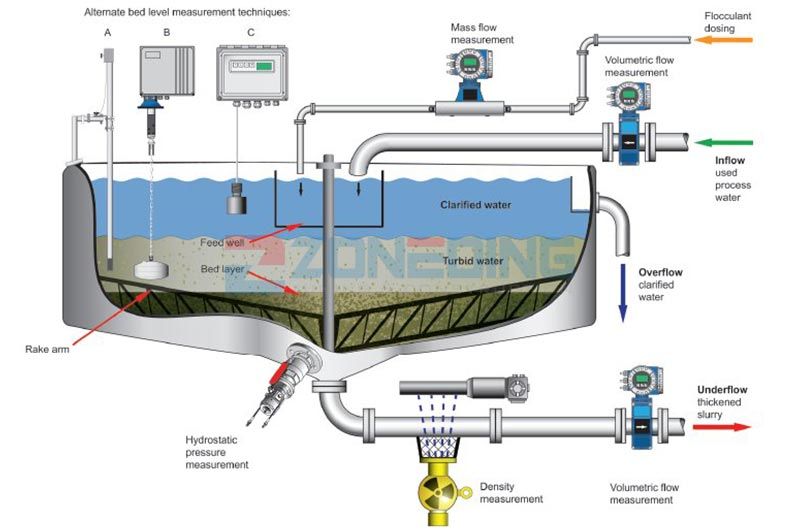

High-efficiency concentrators are generally composed of thickening tanks, rake arms, transmission devices, degassing tanks, feeding devices, discharging port, etc. As shown below:

Customer Case

Specification

High Efficiency Concentrator

| Model | GW-3 | GW-5 | GW-8 | GW-10 | GW-12 | GW-20 | GW-30 | GW-40 | GW-50 |

| Filter area(m2) | 3 | 5 | 8 | 10 | 12 | 20 | 30 | 40 | - |

| Cylinder size(mm) | φ1068×1060 | φ1600×1060 | φ2000×1500 | φ2000×1750 | φ2000×2000 | φ2500×2650 | φ3350×3000 | φ3350×4000 | φ3350×5000 |

| cylinder speed(r/min) | 0.156-1.56 | 0.156-1.56 | 0.1-0.6 | 0.1-0.6 | 0.1-0.6 | 0.14-0.54 | 0.12-0.56 | 0.12-0.56 | 0.12-0.56 |

| Vacuum pressure(KPa) | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 |

| Swept volume(m3/min.m2) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Blast pressure(Kpa) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

| Blast volume(m3/min.m2) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

| Capacity(t/h) | 0.8-1.5 | 1.6-2.4 | 2.8-3.6 | 3-4 | 3-5 | 3-8 | 4.5-12 | 6-16 | 7.5-20 |

| Cylinder motor(kw) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 3 | 4 | 4 | 5.5 |

| Stirring motor(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 4 |

| Weight(kg) | 2635 | 2850 | 5455 | 6317 | 6365 | 10600 | 17200 | 19500 | 21500 |

Zoneding Machine

Zoneding Machine