Mineral Jig Concentrator

Jig concentrator (jig separator, jig machine) is a equipment that drives pulses of water upwards through a thick bed of settled sediment to keep it loose and agitated. This achieves gravitational separation by allowing the denser minerals to sink easily and quickly through the lighter minerals.

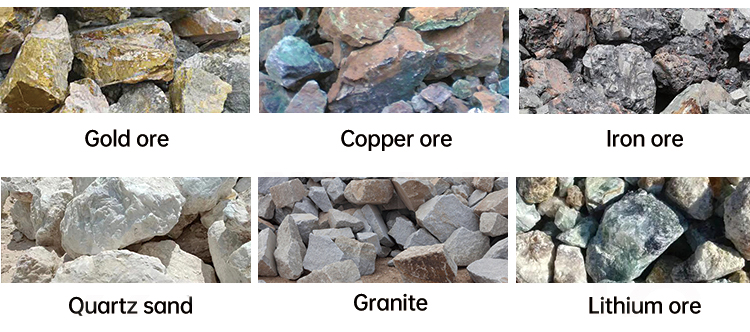

Application of Jigger Machine

Jigger Machine is a gravity separator machine used to separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc.

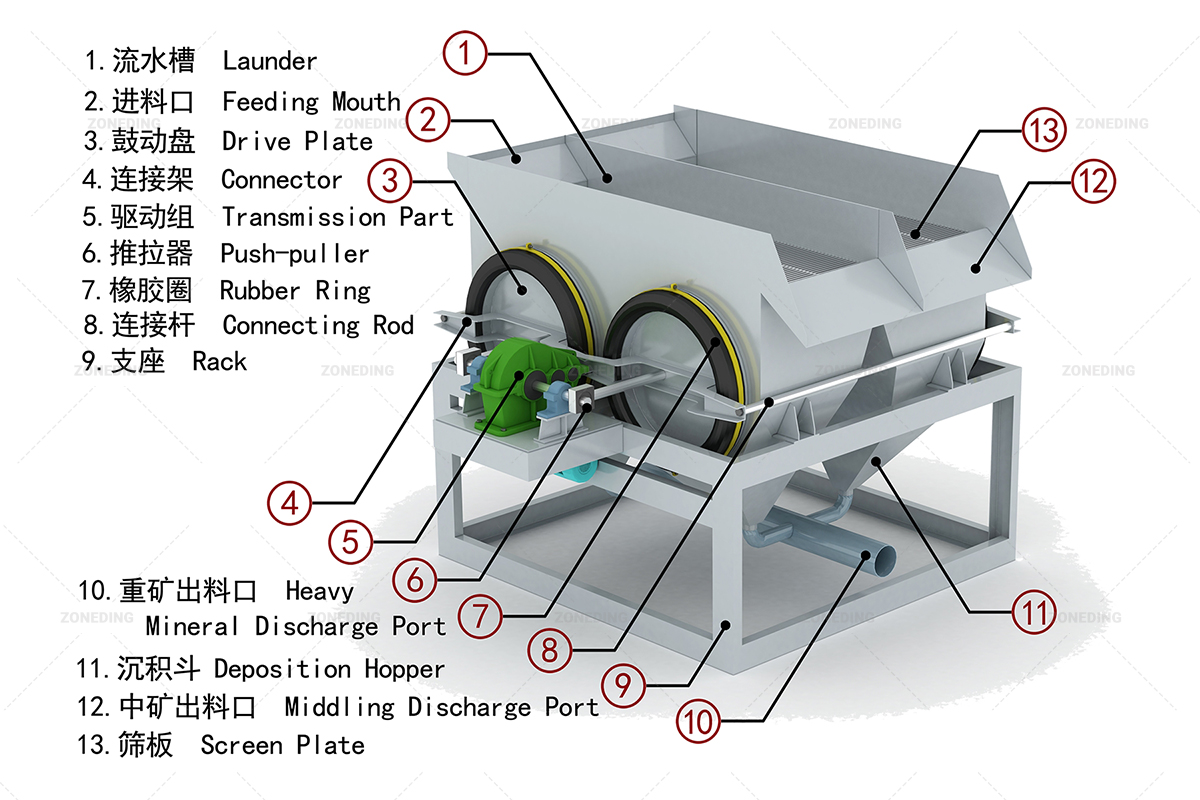

The structure of the Jigger Machine

Centrifugal Concentrator mainly consists of rotating body, electric motor, feeding and discharging ports. The motor drives the rotating body to rotate at a high speed, generating centrifugal force, separating and concentrating the materials in the concentrating chamber, and finally discharging them through different discharge ports.

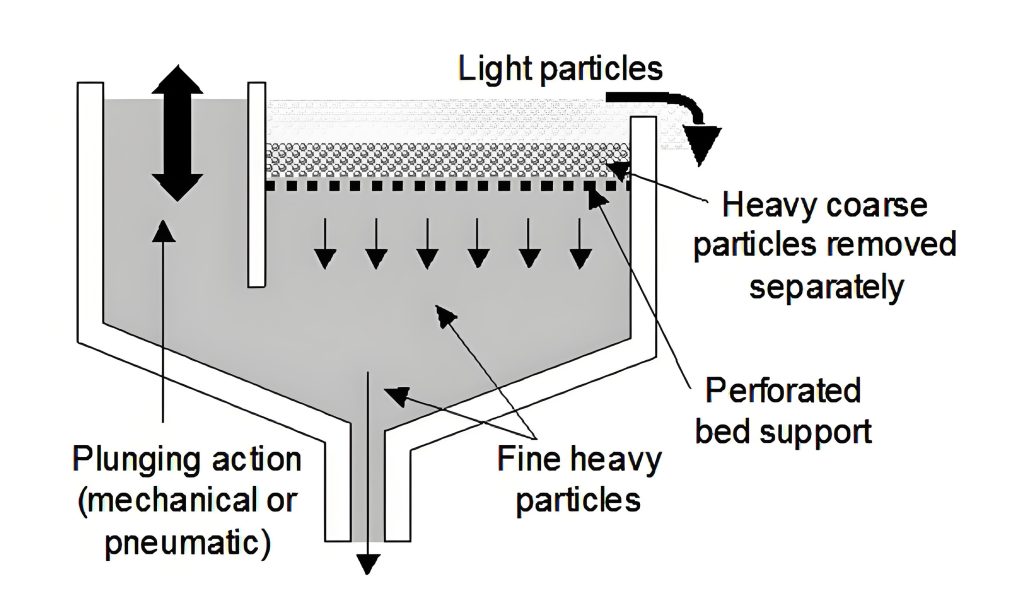

Working Principle Of Mineral Jig Concentrator

The selected ore is continuously fed to the sieve plate of the jig chamber to form a thick material layer. The rising water flow is periodically blown through the sieve plate, causing the bed to rise and loosen, and then the water flow descends (or stops rising).

During this process, heavy minerals enter the lower layer and light minerals transfer to the upper layer. It is difficult for materials with low density to enter the lower space through the material layer with high density. Heavy minerals enter the concentrate tank through the screen, and light minerals enter the tailings tank for discharge.

Advantages Of Mineral Jig Concentrator

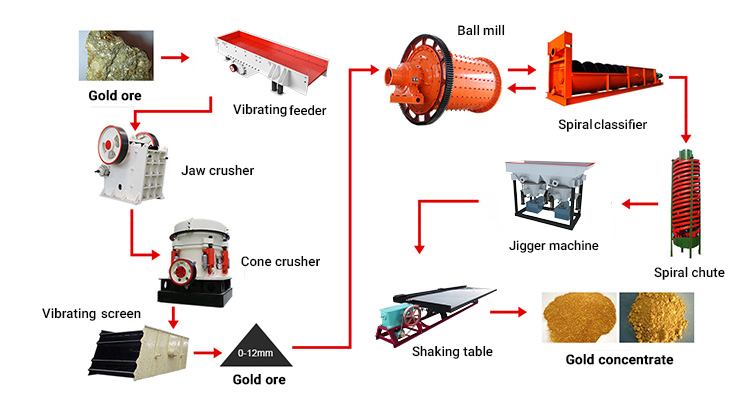

- It can be connected with a trommel screen, rotary scrubber, gold sluice box and other equipment to form a small-scale mobile jig plant, used in gold and diamond washing processing plants.

- High recovery rate – recover 0.5% to 30% concentrate, increasing recovery rate.

- Wide feed and particle size recovery – feed size up to 30mm, which reduces the step of prescreening the feed. Improve the potential for gravity recovery and avoid excessive grinding

- High efficiency – It occupies a small area and is simple and convenient to operate. Energy-saving and environmentally friendly mineral processing equipment newly developed and produced in recent years. It has an excellent effect on the beneficaition of various metal and non-metallic minerals.

Customer site

Specification

Mineral Jig Concentrator

| Model | jigging chamber | diaphragm | Feeding size(MM) | Back Wash Water (M3/H) | Back Wash Water Pressure(Mpa) | Process Capacity (T/H) | Motor power (KW) | Dimension (MM) | Weight (Ton) | ||

| Shape | Area | Stroke | Jig frequency | ||||||||

| JT0.57-1 | Trapezoid | 0.57 | 10-17 | 80-120 | <10 | 18-20 | ≥0.1 | 1-3 | 1.5 | 1550x780x1530 | 0.6 |

| JT1-1 | Trapezoid | 1.1 | 10-17 | <10 | 20-30 | 2-4 | 2.2 | 2270x1110x1890 | 0.9 | ||

| JT2-2 | Trapezoid | 2.3 | 10-17 | 60-100 | <25 | 40-50 | 4-8 | 3 | 2900x1550x2000 | 1.4 | |

| JT4-2 | Trapezoid | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 7.5 | 3900x2000x2460 | 3.2 | ||

| JT4-2A | Trapezoid | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 4*2pcs | 3900x2000x2460 | 4 | ||

| JT5-2 | Trapezoid | 5 | 20-30 | <25 | 80-100 | 10-20 | 7.5 | 4000x2050x2660 | 3.2 | ||

| JT6-3 | Trapezoid | 6.8 | 20-30 | <25 | 120-150 | 20-25 | 7.5+4 | 5400x2000x2460 | 5 | ||

Zoneding Machine

Zoneding Machine