Mixer

A spiral chute, also called mineral spiral separator, is a kind of gravity separation equipment. It makes use of the inertial centrifugal force generated by the ore pulp in the spiral rotation motion to separate light and heavy minerals.A spiral chute combines the features of a spiral concentrator, vibrating table, and centrifugal concentrator. It is the best equipment for mining and beneficiation, especially for placer mining on seashores, riversides, sand beaches, and streams.

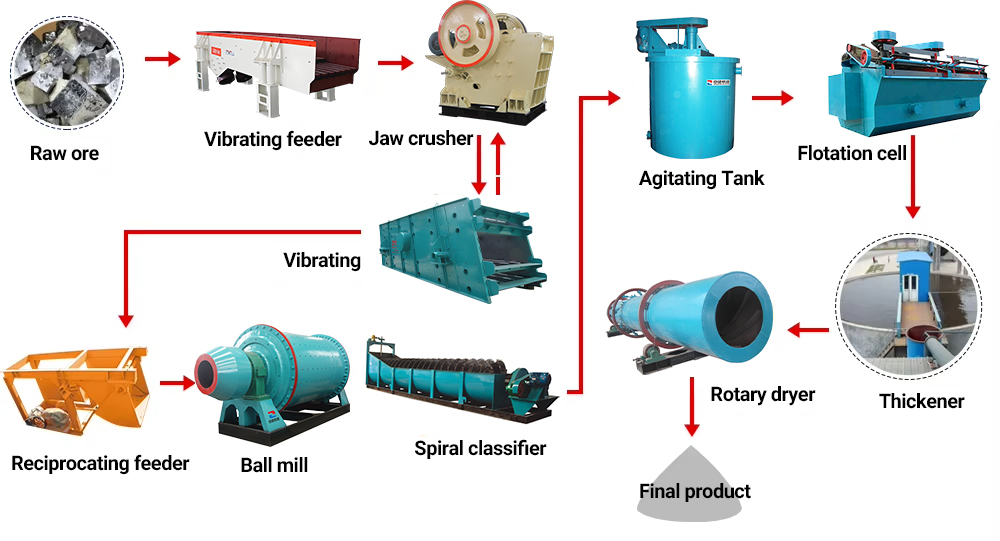

Application of mixing tank

Agitation tank is mainly applied in slurry stirring before the flotation, chemical and construction industry, cyanide chemical plant, sewage treatment plant, and coal plant etc.

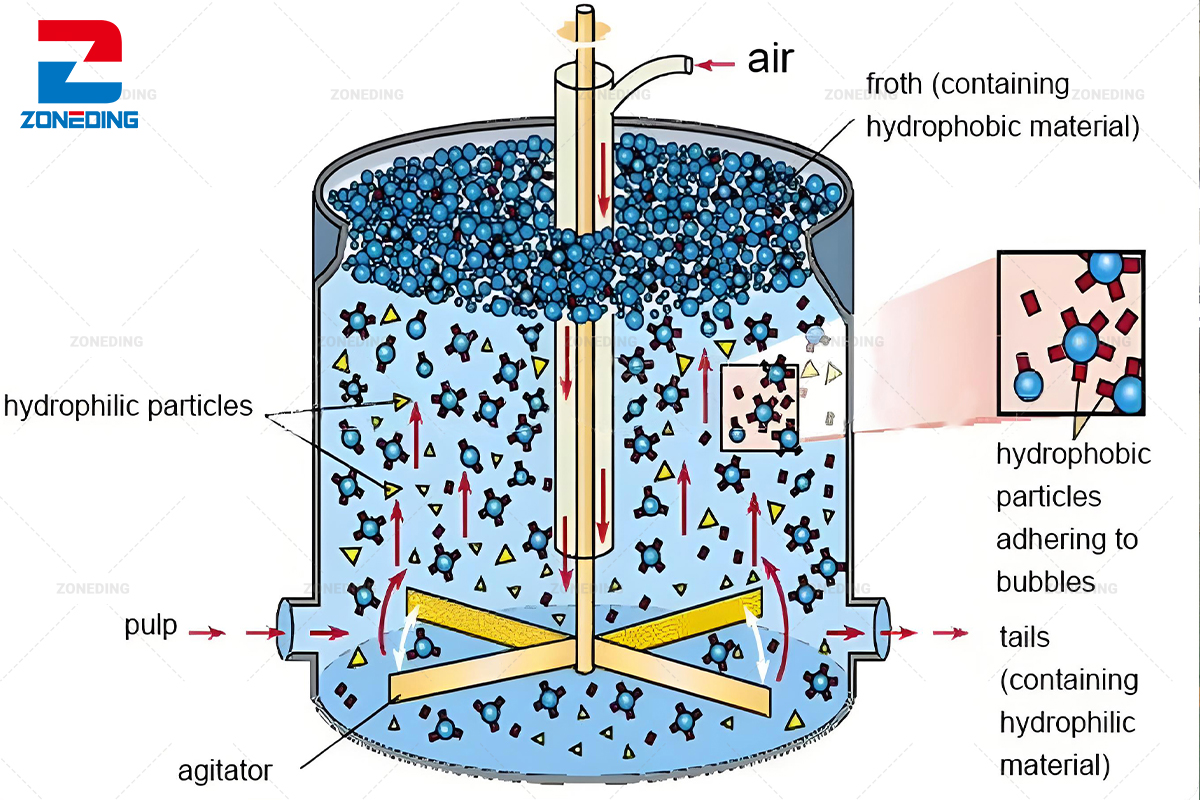

Working Principle Of Mining Mixing Tank

When the machine works, the pulp and pharmaceutical take circular motion by the rotation of the impeller to get mixed evenly in the whole tank, and then the mixed suspension liquid discharges from the overflow part.

Features of mixing barrel

- Compact structure and reliably sealing. Besides, there is an ash damper installed at the mouth of the discharging gate, which can prevent water and flog to enter in.

- It has advantages of evenly mixing, sector shape of propeller and large contacting proportion.

- There are many rows of nozzles, which can guarantee water to flow evenly.

- There is less ash left. Besides, there is a watershed set on the bottom. So the whole machine is very clean.

- Advanced equipment performance. The quality of production is stable. The mixing is even. And the discharging is quick.

Mixing tank process

Customer site

Specification

Mixer

| Category | Specification Model | Dimensions | Effective cubage(m³) | Rotate speed (r/min) | Motor power (kw) | Dimensions (mm) | Total weight (kg) | |

| Diameter (mm) | Height (mm) | |||||||

| Agitating tank | XB-10×10 | 1000 | 1000 | 0.58 | 390 | 1.5 | 1130×1130×1521 | 1050 |

| XB-12×12 | 1200 | 1200 | 1.18 | 390 | 2.2 | 1130×1330×1721 | 1160 | |

| XB-15×15 | 1500 | 1500 | 2.2 | 280 | 3 | 1750×1640×2190 | 1270 | |

| XB-20×20 | 2000 | 2000 | 5.6 | 210 | 5.5 | 2380×2160×2850 | 1700 | |

| XB-25×25 | 2500 | 2500 | 11.2 | 190 | 7.5 | 2990×2720×3540 | 3500 | |

| XB-30×30 | 3000 | 3000 | 19 | 140 | 18.5 | 4030×3270×3010 | 5200 | |

| XB-35×35 | 3500 | 3500 | 29 | 230 | 30 | 3920×3740×4970 | 6630 | |

| XB-40×40 | 4000 | 4000 | 45 | 210 | 37 | 4520×4320×5570 | 7830 | |

| Lifting type | XBT-10×15 | 1000 | 1500 | 1 | 510 | 2.2 | 1130×1130×2070 | 1250 |

| XBT-15×20 | 1500 | 2000 | 2.9 | 400 | 4 | 1636×1768×2785 | 1677 | |

| XBT-20×20 | 2000 | 2000 | 5.6 | 312 | 11 | 2180×2220×3015 | 3100 | |

| High-efficiency leaching tank | XF-20×20 | 2000 | 2000 | 7.07 | 82.5 | 1.5 | 2032×2032×3595 | 2400 |

| XF-25×30 | 2500 | 3000 | 13.5 | 57.6 | 2.2 | 2532×2532×4152 | 3670 | |

| XF-30×30 | 3000 | 3000 | 22.97 | 50 | 2.2 | 3180×3180×4673 | 5340 | |

| XF-35×40 | 3500 | 4000 | 35.6 | 41 | 4 | 3685×3685×5314 | 7140 | |

| XF-40×45 | 4000 | 4500 | 52.78 | 33.5 | 4 | 4185×4185×5814 | 9300 | |

| XF-45×50 | 4500 | 5000 | 74.75 | 33.5 | 5.5 | 4685×4685×6466 | 10500 | |

| XF-50×56 | 5000 | 5600 | 102.1 | 30.6 | 5.5 | 5185×5185×6975 | 12300 | |

| XF-55×60 | 5500 | 6000 | 135.4 | 24.4 | 7.5 | 5670×5670×7569 | 13500 | |

Zoneding Machine

Zoneding Machine