Mobile Jaw Crusher

The mobile jaw crusher is a type of mobile crushing equipment used in the construction and mining industries. It is a self-contained unit that combines a jaw crusher and a mobile carrier, typically mounted on wheels or tracks, allowing it to be easily moved to different locations and set up on job sites.

Application

Portable jaw crusher for sale has a broad range of application fields due to their features of flexibility, mobility, and efficiency. Some of the key application fields for mobile jaw crushers include: mining and quarrying, road construction, construction waste recycling, and concrete production. In the following paragraphs, let’s explore the potential of mobile jaw crushers across these industries.

Mobile Jaw Crusher is widely used in many fields:

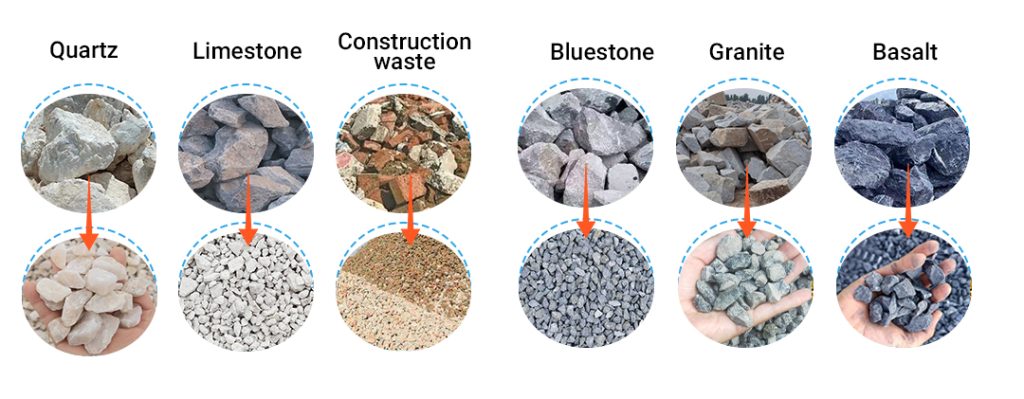

Sand and gravel production: It is used to produce high-quality mechanism sand and aggregate, providing raw materials for construction, highway, railroad and other infrastructure construction.

Mining: In the process of mining, impact crusher can be used for fine crushing operation to improve the utilization rate and grade of ore.

Solid waste treatment: Mobile jaw crusher machine can process construction waste, concrete waste, and other such materials for recycling and reuse. Crushing the waste materials can process them into various construction aggregates, achieving resource recycling and reuse. The high mobility is suitable for direct on-site crushing, reducing transportation costs.

Types Of Mobile Jaw Crushers

Zoneding offers two types of mobile Jaw crushers: tire-type and crawler-type. Here’s a detailed introduction to each:

How Does The Mobile Jaw Crusher Work?

- Loading: Raw materials are fed into the feed hopper through wheel loader or belt conveying.

- Crushing: The movable jaw blade suspension shaft gets to and away the fixed shaft periodically, which causes a press, rubbing and grinding, etc. to the raw materials.

- Screening: The crushed material passes through screens to sort sizes—finer materials fall through, while larger pieces continue to be crushed.

- Discharge: The processed material is discharged via a conveyor system.

Advantages Of Mobile Jaw Crusher

The machine adopts a hydraulic system to drive the tracks, thus realizing smooth walking and being able to adapt to a variety of complex work site conditions.

The integrated mobile unit can be matched with the crushing mainframe according to the customer’s demand. The bottom is equipped with tires for flexible transfer.

Advanced digital technology simplifies the operation process, and the hourly crushing capacity of 1 person is up to 1,000 tons.

The wearing parts are made of special material, super hardness surface wear resistance, long service life.

Customer Site

Zoneding Machine

Zoneding Machine