Palm Fiber Dryer

Palm fiber is the waste material from the production of palm oil. With the rise of the biomass energy industry, the application range of palm fiber has been expanded, solving the environmental pollution caused by palm thread. After being processed by dedicated palm fiber dryer, the moisture content of the finished product is less than 15%, which is proper for pelletizing.

Palm Fiber Dryer Features

1.Designed for fiber materials, with unique structure, low energy consumption and high thermal efficiency.

2.Unique heating method, the color, strength and flexibility of the dried fiber will not change.

3.Variable frequency speed regulation, automatic temperature control, and adjustable operating parameters.

4.It can form a drying production line with fiber cutting machine, screening machine, and packaging machine, or can be used separately.

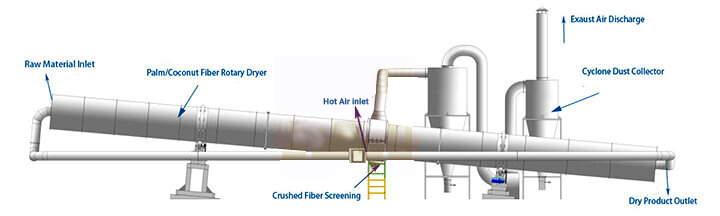

Palm Slag Dryer Working Principle

Palm slag drying production line consists of hot air stove, feeding device, rotary drum dryer, conveyor, dust remover and discharging device. After the sorted palm fiber enters the dryer, it is turned by the uniformly distributed material lifting device in the drum. The material is evenly dispersed and fully contacted with hot air, allowing for rapid heat and mass transfer, drying, and discharging at the discharge port of the drum.

Advantages of Palm Dregs Dryer

- Fully automatic operation, automatic stone and iron removing, automatic feeding, automatic adjustment of drying speed, automatic discharge, saving a lot of labor costs.

- Adopt specially designed disperser in the dryer, which can effectively solve the problems of adhesion and entanglement of sticky materials during the drying process, and improve the drying effect.

- High drying intensity, and the special design of the relevant components can guarantee continuous operation under the condition of full load for a long time.

- Multiple heat sources available: coal, natural gas, biomass pellets, etc.

Specification

Drum Dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Durable Machinery

Durable Machinery