Pomace Dryer For Sale

The pomace dryer can quickly dry the wet fruit residues from 80% moisture content to less than 13%. The rotary drum dryer uses the heat as the energy source, the hot air as the drying medium, and the strong hot air to heat various wet pomace residues. Due to the characteristics of high water content, high sugar content and easy adhesion of pomace, Dongding adopts a series of unique technologies and processes to solve various technical problems in the drying process and achieve good drying effect.

Application of Pomace Dryer

The fruit residues dryer is widely used for drying apple pomace, pineapple residues, citrus pomace, tangerine peel and other fruit pomace. It can also be used to dry distiller’s grains, bagasse, cassava residues, olive pomace, bean dregs, etc.

Advantage of Pomace Dryer

1.Compared with single drum rotary dryer, the length of the triple pass rotary drum dryer is shortened by 50%, reducing the building area and saving about 40% project investment.

2. The rotary dryer has large processing capacity, strong anti-overload capability, low energy consumption, directly reduce the drying cost.

3. The use of co-current, counter-current, mixed-current and other drying technologies greatly improves the thermal efficiency.

4. The material flow is controlled by frequency conversion, which can be easily adjusted according to user needs.

5. Multiple heat sources can be selected.

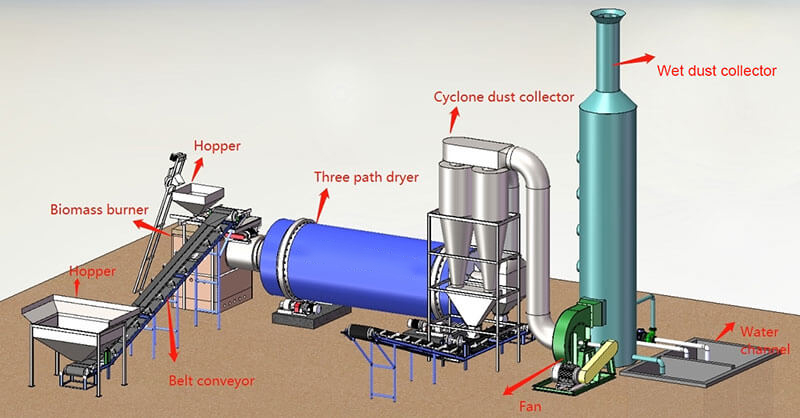

Pomace Dryer Process

After dehydration, the wet fruit residue enters the dryer. It is evenly dispersed in the dryer and fully contacted with the hot air under the flipping of the evenly distributed lifting plate, accelerating the drying process. During the drying process, the fruit residue is discharged from the other end of the dryer under the action of the inclined lifting plate and the heat medium.

Specification

Drum Dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Durable Machinery

Durable Machinery