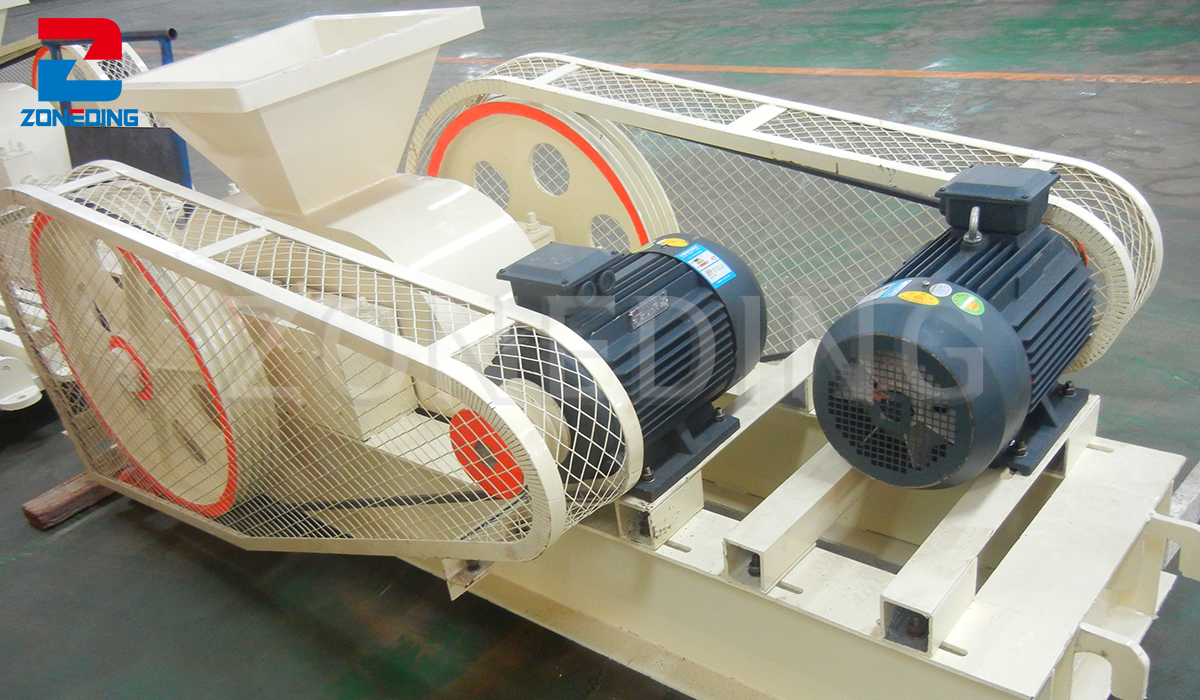

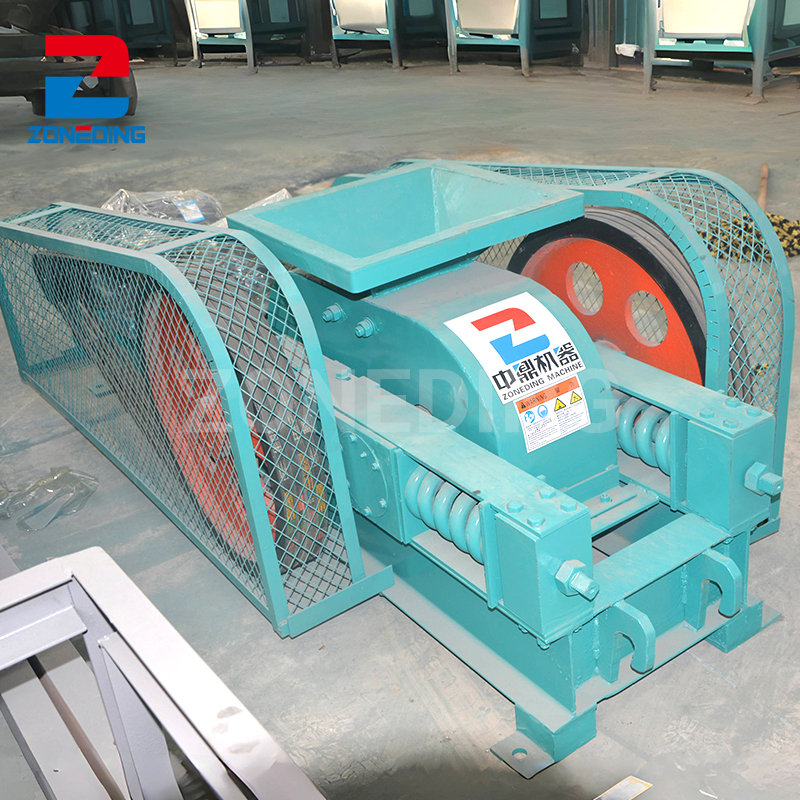

Roller Crusher

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc.

The Roller Crusher Key Applications Include

The roller crusher, also known as roll crusher machine, has a wide range of applications across various industries.

Roll Crusher is suitable for River gravel, iron ore, limestone, basalt, quartz, granite and other medium or hard ores and rocks in metallurgy industry, cement industry, power department, construction, phosphate, refractory industry, etc.

Features of Roller Crusher

- High-efficiency crushing: The roll crusher has high-efficiency crushing ability, which can quickly crush materials of various hardness and improve production efficiency. Meanwhile, its crushing granularity is adjustable, which can be flexibly adjusted according to customers’ demands.

- Stable and reliable: The machine adopts advanced mechanical structure and transmission system to ensure the stability and reliability of the equipment during operation and reduce the failure rate. In addition, the roller crusher also has overload protection function, which effectively protects the equipment from damage.

- Wear-resistant and durable: the main parts of the roller crusher are made of high-strength wear-resistant materials, and after special treatment, they have excellent wear-resistance and impact-resistance, which prolongs the service life of the equipment.

- Easy to operate: The machine adopts humanized design, which is easy to operate and understand. Meanwhile, equipped with intelligent control system, it can realize automatic operation and reduce labor intensity.

- Energy saving and environmental protection: the roller crusher adopts closed structure in the crushing process, which effectively reduces dust emission and meets the requirements of environmental protection. At the same time, the machine is also equipped with energy-saving design, reducing energy consumption and realizing green production.

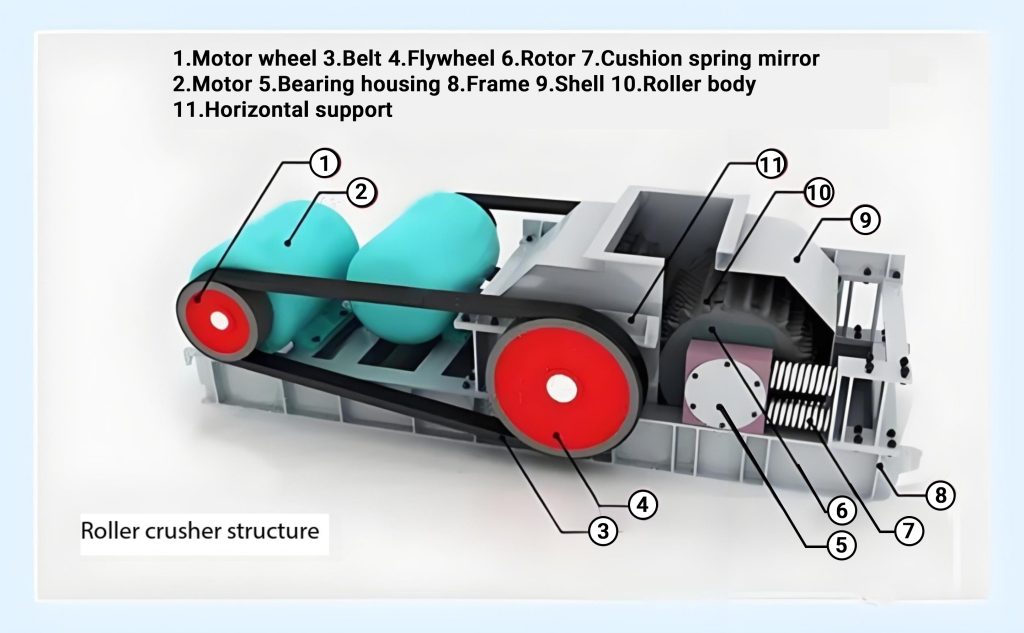

Structure of Roll Crusher

How does a Roller Crusher work?

The working principle of Roller Crusher is mainly to crush the materials by squeezing and shearing the materials by two relatively rotating rollers, so as to realize the crushing of materials. After entering the crushing chamber, the material is squeezed and sheared by the rollers, and is crushed into the required particle size. Meanwhile, the equipment is equipped with advanced control system, which can monitor and adjust the crushing strength in real time to ensure the crushing effect and the stability of the equipment operation.

Customer Site

Specification

Roller Crusher

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

| Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

Zoneding Machine

Zoneding Machine