Sand Dryer

Sand dryer is a three drum drying equipment developed on the basis of single drum rotary dryer. With simple internal structure and low energy consumption, the sand dryer is deeply loved by users, which greatly improves the labor productivity and application range. Sand dryer is generally suitable for drying materials with large specific gravity, especially for drying river sand, silica sand, yellow sand, sea sand, ore sand, iron powder, copper slag and other materials.

Sand Dryer

Three-drum Dryer

Three-drum Dryer

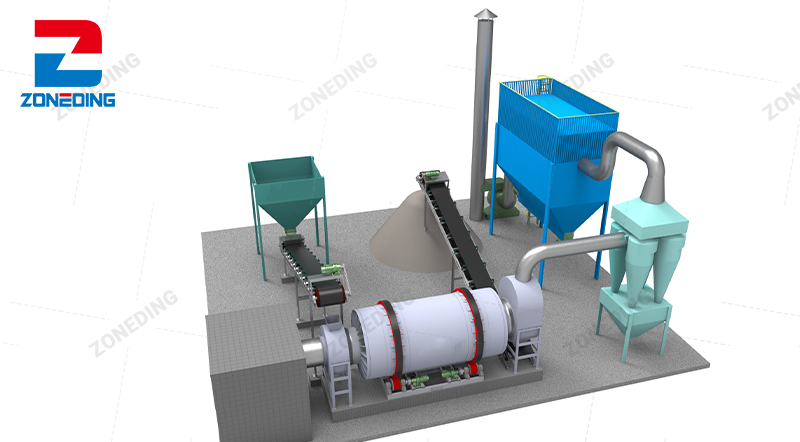

Rotary Sand Dryer Application

The sand rotary dryer is mainly used for drying river sand, artificial sand, quartz sand, dry mortar, yellow sand, slag, clay, limestone, and other materials with high wetness and high specific gravity. It is widely used in building materials, metallurgy, mineral processing, chemical, cement and other industries.

Main Features of Rotary Sand Dryer

- The rotary dryer has compact structure and reasonable layout, improves the heat exchange rate between materials and heat energy and ensures good drying effect.

- The new lifting plate device is adopted to make the combination of materials and drying heat source more fully, and greatly improve the drying efficiency.

- High automation degree. According to the water content and output of the materials, the frequency conversion control system is used to control the cylinder speed.

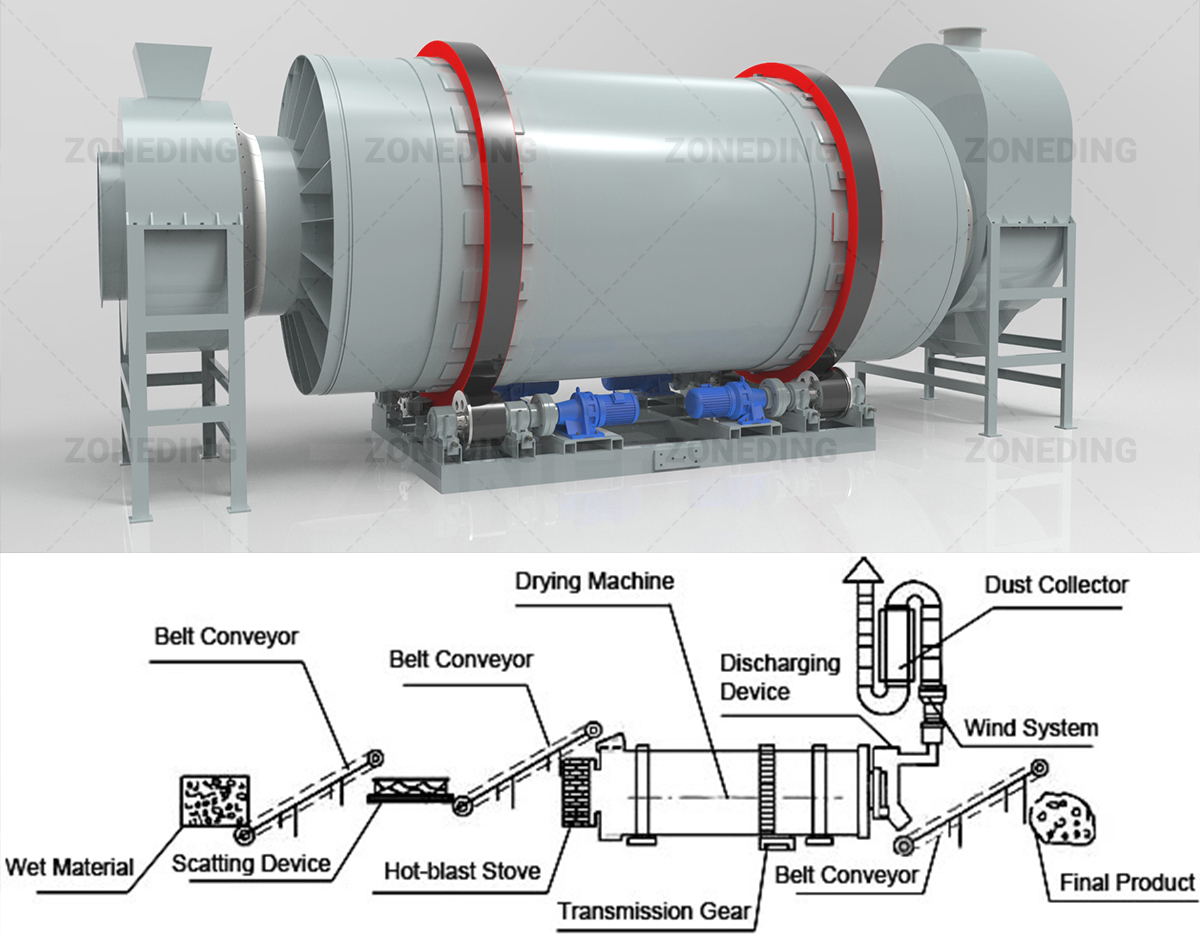

Working process

Materials enter the inner side of the drum through the feeding device to realize current flow drying process. They get raised and scattered under the shoveling plate in a spiral advancing way to exchange heat.

Then the materials enter the middle layer of the inner wall through the other end to realize the counter current drying process. They are lifted in over and over in the middle layer advancing in two-steps forward and one-step back way.

They absorb heat from both inner drum and middle drum, which extends the drying time and realizes the best drying condition. Finally, materials fall into the external layer of the drum from the other end of the middle layer, processing in a rectangle multi-loop way.

The dried materials move quickly out of the drum under the hot air, while the wet ones remain to stay in the drum because of their own weight. Materials are dried completely inside the rectangle shoveling plate and then cooled by the single drum cooler, thus finishing the whole drying process.

Sand dryer process

Customer Site

Specification

Sand dryer

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Diameter of outer cylinder(m) | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 |

| Length of outer cylinder(m) | 7 | 7 | 7.0 | 7.0 | 8 |

| Cylinder volume( m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Rotating speed of cylinder(rpm) | 4-10 | 4-10 | 4 -10 | 4 -10 | 4 -10 |

| Initial moisture of slag(%) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag(%) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground(%) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (%) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature(℃) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity(T/h) | Yellow sand:25-30 Slag: 20-25 | Yellow sand:30-35 Slag:25-30 | Yellow sand:35-40 Slag:30-35 | Yellow sand:45-50 Slag:35-40 | Yellow sand:65-70 Slag:60-65 |

| Motor type | Y2-132m-4E | Y2-132m-4E | Y2-160m-4 | Y2-160m-4 | Y2-160m-4 |

| Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

| Reducer type | XWD7-23-11W | XWD7-23-11W | XWD6-23-7.5KW | XWD6-23-7.5KW | XWD8-23-15KW |

| Velocity ratio of reducer | 29 | 29 | 29 | 29 | 29 |

Durable Machinery

Durable Machinery