Shaking Table

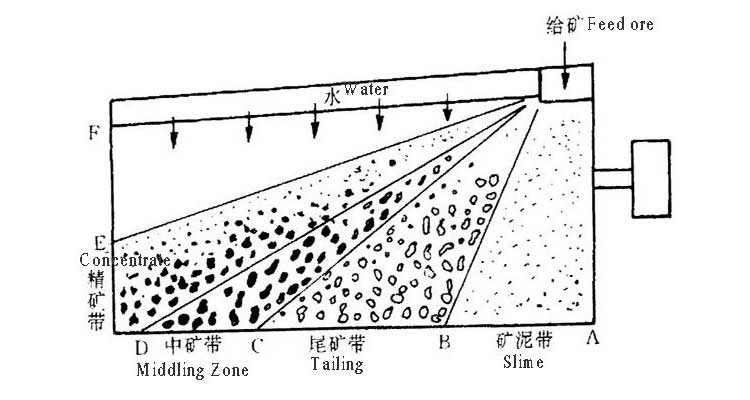

The shaking table is a gravity separation machine that uses the combined action of mechanical vibration and water washing to separate granular materials according to density.

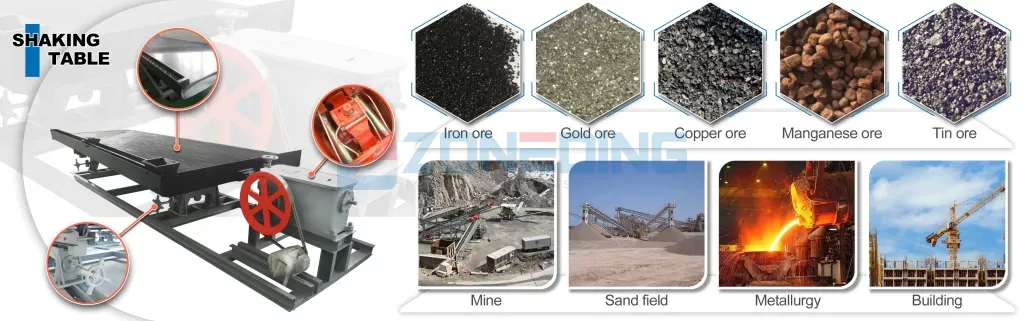

Application of Shaking Table

Coal, gold ore, iron ore, magnesite, copper ore, manganese ore, tin ore, tungsten ore, chromium ore, titanium ore and other rare metal and precious metal ores. It can also be used for purifying non-metallic minerals, such as talc, limestone, garnet, pyrophyllite, etc.

Shaking table mechanism

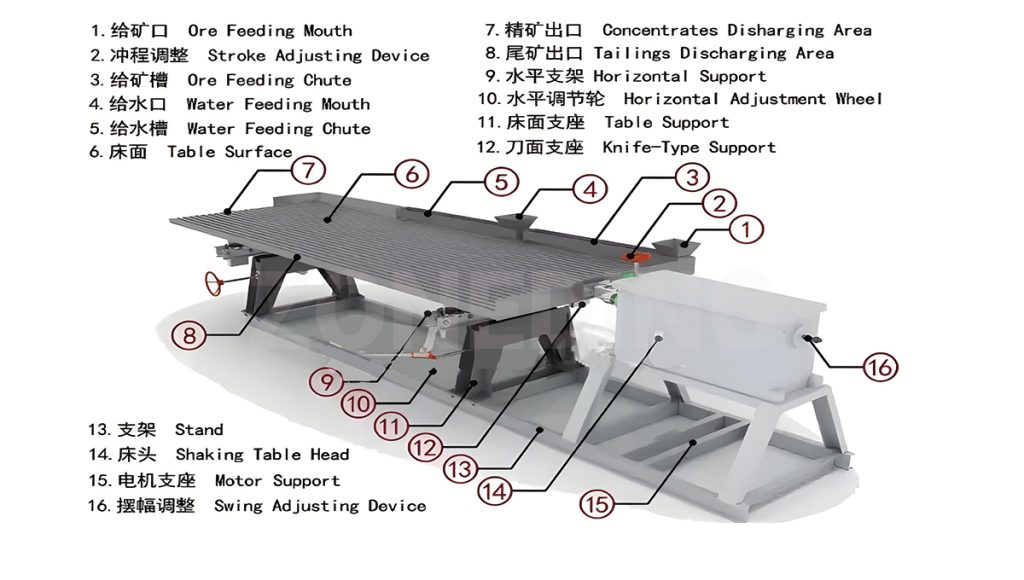

- Bed head: contains the electric motor, transmission device, to provide power for the shaking table.

- Bed surface: the working area for ore sorting, made of wear-resistant material with bed strips.

- Slope adjuster: used to adjust the inclination angle of the bed to optimize the sorting effect.

- Water Tank: Provides the water flow required for sorting to help loosen and stratify the ore.

- Tanks: hold the ore to be sorted.

- Rifling bars: guide the movement of the ore on the bed.

- Lubrication System: Ensures smooth operation of shaking table components and reduces wear and tear.

The Working Principle of Shaking Table

The shaking table of Zhongding machine mainly relies on its unique shaking trajectory and bed design to realize the separation of minerals. When the motor starts, the power is transmitted to the crankshaft of the shaking table through the transmission device such as belt or gear. The crankshaft then rotates, driving the connecting rod and rocker for up and down or back and forth reciprocating motion. This movement makes the bed surface produce certain vibration and tilt, so that the mineral particles in the bed surface for layering and movement.

Advantages of Shaking Table

- High-efficiency separation: unique shaking track and bed design ensure fast and accurate separation of minerals with different densities.

- Stable and durable: made of high-quality materials with sturdy structure, it can work continuously for a long time to ensure uninterrupted production.

- Intelligent operation: Equipped with advanced automatic control system, the operation is simple and intuitive, reducing manual intervention and improving production efficiency.

- Environmental protection and energy saving: optimized power system and energy-saving design reduces energy consumption and helps the development of green mining industry.

- Widely applicable: suitable for gold, silver, copper and other minerals processing, to meet the separation needs of different minerals.

Customer site

Specification

shaking table

| Deck type | Unit | Coarse sand | Fine sand | Slime Deck | Three different kinds of decks are available | |||

| Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

| Deck Size | Length | mm | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 |

| transmission end width | mm | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | |

| Concentrate end width | mm | 1546 | 1546 | 1546 | 1100 | 850 | 430 | |

| Maximum Feeding Size | mm | 2 | 0.5 | 0.15 | 0.1-2 | 0.074-2 | 0.074-2 | |

| Feeding Amount | t/d | 30-60 | 10-20 | 15-25 | 0.4-1.5t/h | 0.3-0.8t/h | 0.05-0.2t/h | |

| Feeding Density | % | 25-30 | 25-30 | 15-25 | 10-30 | |||

| Stroke | mm | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | |

| Frequency | f | 45-48 | 18-53 | 50-57 | 210-320 | 250-450 | 280-460 | |

| Water added | t/d | 80-150 | 30-60 | 10-17 | 0.3-1.5t/h | 0.2-1t/h | 0.1-0.5t/h | |

| Transverse slope of Deck | / | 2° 30-4° 30 | 1° 30-3° 30 | 1° -2° | 0 -10° | 0 -8° | 0 -10° | |

| Longitudinal slope of Deck | / | 1.4 | 0.92 | —— | —— | —— | —— | |

| Cross-section Shape of Deck | rectangular | saw tooth | triangle | Avaliable rectangular, saw tooth, triangle | ||||

| Motor Power | KW | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

Zoneding Machine

Zoneding Machine