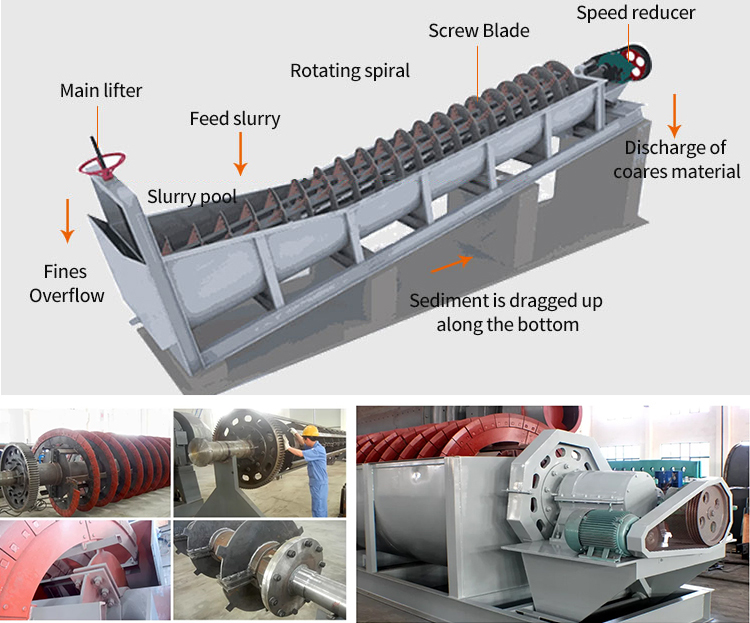

Spiral Classifier

Spiral classifier is also known as screw classifier. It can conduct different grading operations based on the principle that different solid particles have different settling velocities in the liquid.

Classification of spiral classifier

There are four classifiers: high weir single spiral and double spiral, submerged single spiral anddouble spiral.

High weir spiral classifier is suitable for coarse particle classification, the maximum size of overflowis generally 0.4~0.15mm;

Submerged spiral classifier is suitable for fine particle classification, the maximum size of overflow isgenerally below 0.2mm.

Features of Spiral Classifier

- High-efficiency grinding: The rod mill adopts optimized grinding media and grinding chamber design to ensure that the materials are fully ground during the grinding process and improve the grinding efficiency.

- Uniform particle size: Through the uniform distribution of rod-shaped grinding media and rotary movement, the rod mill can realize uniform distribution of material particle size, to meet the needs of different industries for particle size requirements.

- Stable and reliable: the equipment has a solid structure, smooth operation, excellent durability and stability, ensuring long-term stable operation and reducing maintenance costs.

- Energy-saving and environmental protection: the rod mill adopts advanced energy-saving technology to reduce energy consumption, and at the same time reduces noise and dust emissions, in line with environmental requirements.

- Easy to operate: the equipment is equipped with intelligent control system, which is simple and intuitive to operate, reduces the operation difficulty and improves the production efficiency.

How does a Features of Spiral Classifier work?

The working principle of the rod mill is based on the rotation and impact action of the rod-shaped grinding media in the grinding chamber. When the rod mill starts, the motor drives the grinding chamber to rotate, and the rod-shaped grinding media moves with it. After the material enters into the grinding chamber, it is impacted and grinded by the rod-shaped grinding media, and gradually refined to reach the required particle size. At the same time, by adjusting the number, size and rotation speed of the grinding media, it can realize the precise control of the material grinding effect.

Customer Site

Specification

Spiral Classifier

| Model | Spiral Diameter (mm) | Trough Length (mm) | Spiral rotate speed (r/min) | Processing capacity(t/d) | Motor Power(kw) | Dimensions(mm≤) | Total weight (t) | ||||

| Sand -return | Overflow | For driving | For lifting | Length | Width | Height | |||||

| FG-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | —- | 3850 | 490 | 1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | —- | 5430 | 680 | 1480 | 1.9 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | —- | 6720 | 980 | 1820 | 3.1 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | —- | 7590 | 1240 | 2380 | 4.9 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | —- | 9600 | 1240 | 2680 | 6.2 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 | 20.5 |

| FC-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 | 26.8 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | 41 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 | 73 |

| 2FG-30 | 14300 | 23300 | 1410 | —- | —- | 17091 | —- | 8680 | 84.8 | ||

Zoneding Machine

Zoneding Machine