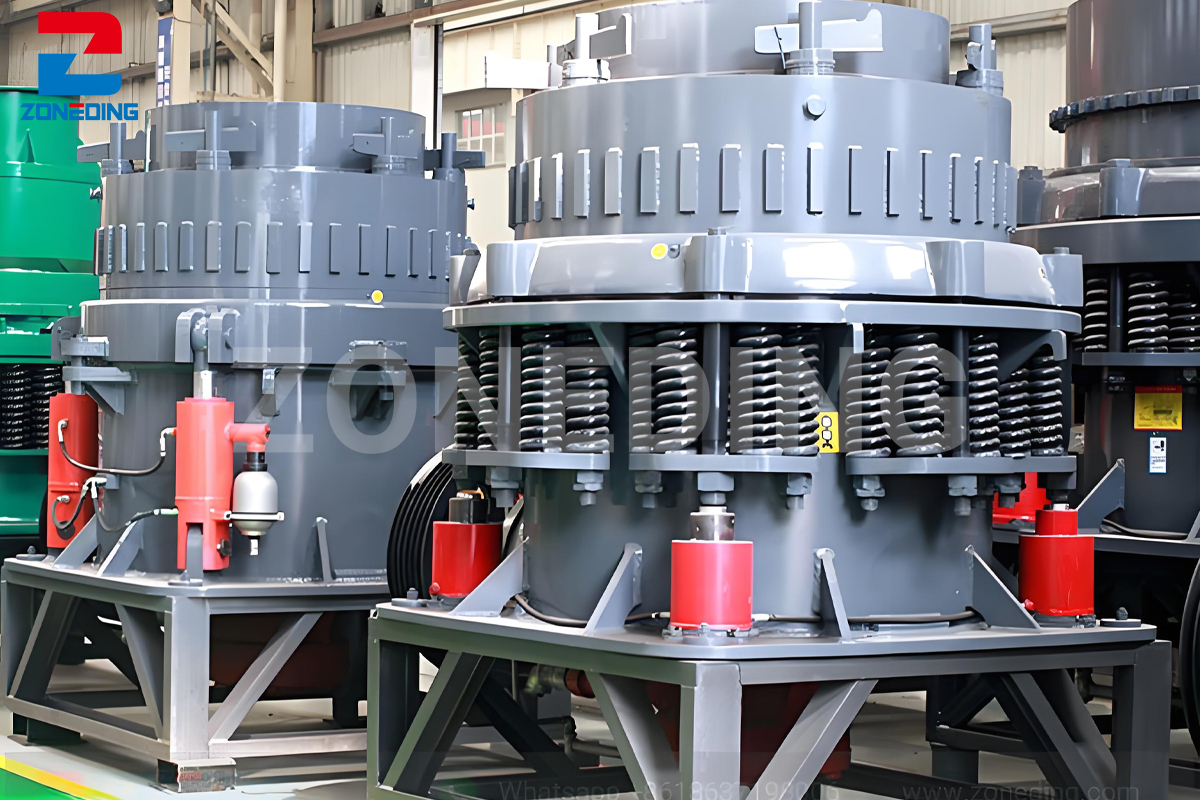

Spring Cone Crusher

Spring cone crusher is is the earliest cone crushing equipment which adopts the laminating crushing principle. It is suitable for the medium, fine and super fine crushing of moderate hardness rocks and ores.

Features of Spring Cone Crusher

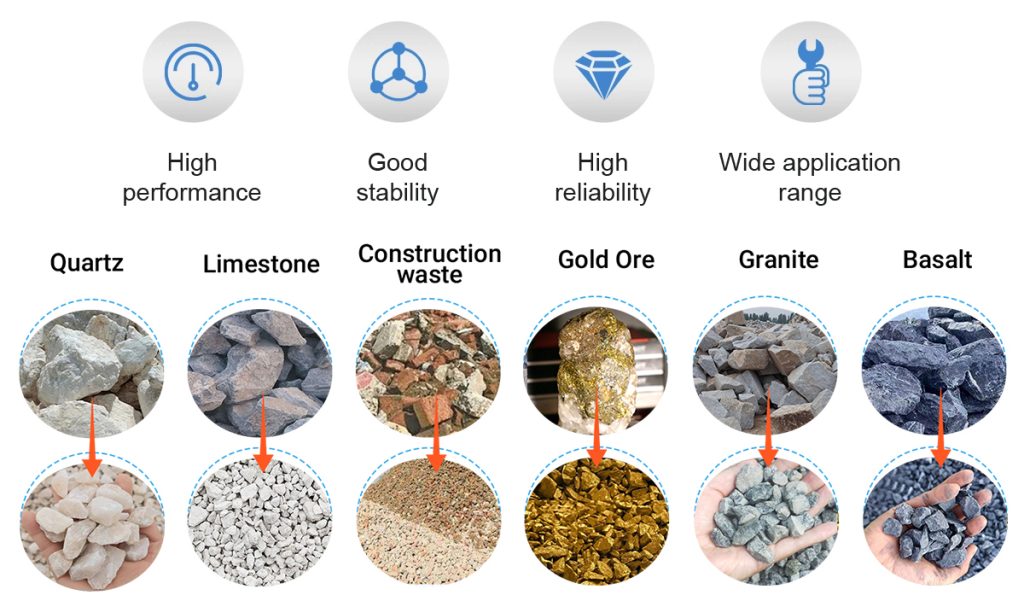

- Efficient crushing: The machine has strong crushing capacity and can handle materials of various hardnesses with high crushing efficiency to meet the demand of large-scale production.

- Stable and Reliable: Made of high strength materials, the structure is sturdy and durable, which ensures the stable operation of the machine even under the harsh environment.

- Intelligent adjustment: Equipped with advanced control system, the crushing strength can be adjusted automatically according to the characteristics of materials, realizing intelligent operation.

- Energy saving and environmental protection: The optimized design of crushing chamber and discharge system reduces energy consumption and dust emission, which is in line with environmental protection requirements.

- Convenient maintenance: the modularized design makes the maintenance and replacement of parts more convenient and reduces the maintenance cost.

Structure of spring cone crusher

Spring cone crusher is widely used in stone crushing operation in mining, metallurgy, construction, highway, railroad and other fields. Whether it is used for crushing limestone, granite or other hard ores, this machine can meet the production demand with high efficiency and stable performance.

How does a Spring Cone Crusher work?

The machine is driven by the motor to rotate the eccentric shaft, which drives the crushing cone to do the rotary pendulum movement in the crushing cavity. The material is fed from the top of the crushing chamber and crushed under the extrusion and impact of the crushing cone. The crushed material is discharged from the bottom of the crushing chamber. When encountering non-crushable materials, the spring safety system will automatically adjust the position of the crushing cone, so that the non-crushable materials can be discharged from the crushing chamber, thus protecting the equipment from damage.

Spring Cone Crusher Process

Customer Site

Specification

Spring Cone Crusher

| Specification | Model | Diameter of large end of crushing cone (mm) | Max.feeding size (mm) | Width of discharge opening (mm) | Processing capacity (t/h) | Motor power (kw) | Total weight(t) | Dimensions(mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

Zoneding Machine

Zoneding Machine