Sugarcane Dryer

Sugarcane is one of the main sources of sugar. Sugarcane residues from sugar processing are mainly used to make paper or as fuel. The first step in reusing sugarcane is to remove moisture. Treatment and reuse dryers are mainly used for the dewatering of sugarcane slag. However, sugarcane slag becomes more viscous when it dries. Our sugarcane dryer adopts drum drying technology to solve the problem of easy adhesion and coking of sugarcane during drying.

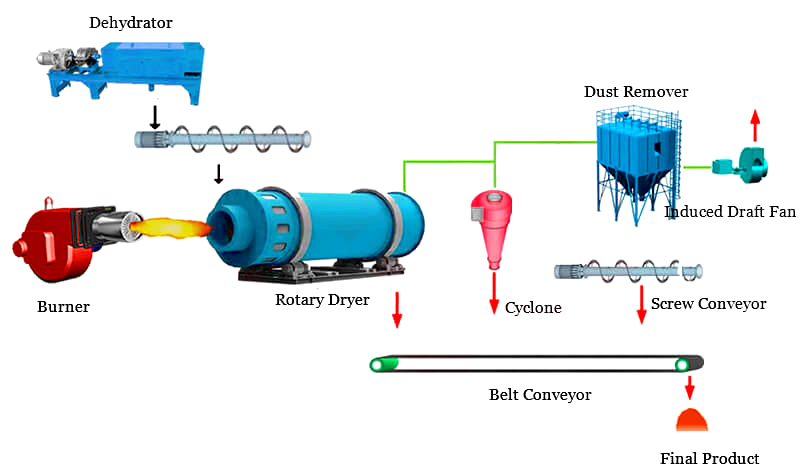

Sugarcane Dryer System

The complete sugarcane slag drying system consists mainly of dewatering equipment, heat source, feeder, drying system, unloader, fan, unloader and distribution cabinet, crushing system, packaging system and other components.

Advantages of sugarcane dryer

1. Low outlet temperature, which ensures the long service life of the dust collector, can be continuously produced for use in the process of descent.

2. Numerous sources of heat. Customers can choose the heating source according to their needs.

3. The system adopts PLC control system, with a high degree of automation and simple operation.

4. The system adopts a unique sealed design with no thermal energy leakage.

5.Low investment, low maintenance, short payback period.

Application of sugarcane dryer

The sugar slag dryer can not only be used to dry sugar slag, but also to dry fruit slag, beet slag, starch, corn slag, soybean slag, pharmaceutical slag and other materials with high moisture and viscosity.

Specification

Drum Dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Durable Machinery

Durable Machinery