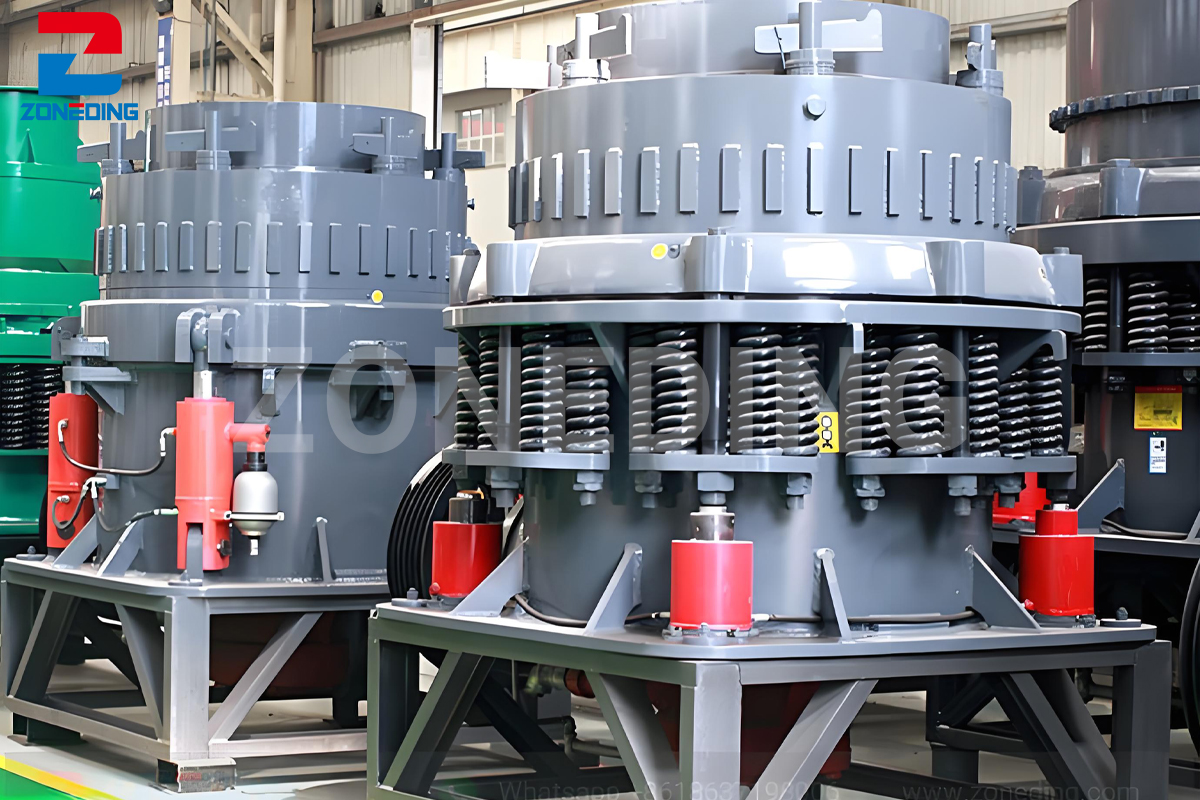

Application

Symons cone crusher is widely used in mining, metallurgy, construction, highway, railroad and other industries, suitable for crushing various hardness of ores, rocks, construction waste and other materials. Whether it is a large mine or a small quarry, you can find a place for Symons cone crusher.

Features of Symons Cone Crusher

- High-efficiency crushing, excellent output: Simmons Cone Crusher adopts optimized crushing cavity design with high crushing efficiency and high output, which can greatly improve the production efficiency and reduce the operating cost.

- Wear-resistant and durable, excellent quality: the key parts of the machine are made of high-strength alloy materials, which are precisely processed and heat-treated to provide excellent wear-resistance and durability, ensuring long-term stable operation.

- Intelligent control, safe and reliable: Equipped with advanced hydraulic system and electronic control system, it realizes automatic adjustment of crushing strength, simple and convenient operation, safe and reliable, and reduces failure rate.

- Environmental protection and energy saving, green production: optimize the crushing process, reduce dust emission, meet the requirements of environmental protection; at the same time, the machine adopts energy-saving design, reduce energy consumption, realize green production.

- Convenient maintenance and time-saving: modular design makes it more convenient to replace wearing parts, reduces downtime and improves the utilization rate of the equipment.

How does a Symons Cone Crusher work?

The working principle of Symons Cone Crusher is that the main shaft is driven by electric motor to rotate and drive the crushing cone to do rotary oscillation movement in the fixed cone liner. The material is crushed by extrusion, grinding and shearing in the crushing chamber. The crushed material is discharged through the discharge port to complete the whole crushing process. Meanwhile, the hydraulic system and electronic control system monitor and adjust the crushing force in real time to ensure the crushing effect and stable operation of the equipment.

Specification

Symons Cone crusher

| Model | Cavity Type | Stroke(mm) | Max. Feeding Size(mm) | Discharging Opening Adjusted Scope(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) |

| CS1400C-D | Coarse | 30 | 235 | 30-60 | 210-530 | 220 | 25 |

| CS1400Z-D | Medium Coarse | 30 | 215 | 25-50 | 200-500 | 220 | 25 |

| CS1400Z-X | Medium Coarse | 25 | 180 | 22-45 | 180-475 | 220 | 25 |

| CS1400S-X | Fine | 25 | 100 | 19-40 | 130-260 | 220 | 25 |

| CS1200C-D | Coarse | 22 | 180 | 19-50 | 110-250 | 132 | 16 |

| CS1200S-X | fine | 15 | 80 | 16-40 | 80-180 | 132 | 16 |

Zoneding Machine

Zoneding Machine