Toothed Roller Crusher

Toothed roller crusher is a new type of high efficiency crusher. With its recognized operation degree,the applications of toothed roller crusher in coal, cement, building industry, metal mines and non metal mine industry will increase.

Features of Toothed Roller Crusher

- Efficient Crushing: Adopting specially designed rollers, it can quickly and effectively crush various materials and improve production efficiency.

- Adjustable particle size: By adjusting the gap of the toothed rolls, the particle size of the discharged material can be easily controlled to meet different production requirements.

- Low energy consumption: optimized power system and energy-saving design reduces energy consumption and saves operation cost for enterprises.

- Easy maintenance: the equipment structure is simple, easy to maintain and repair, reducing downtime and maintenance costs.

- Safe and reliable: equipped with multiple safety protection devices to ensure the safety of equipment and operators.

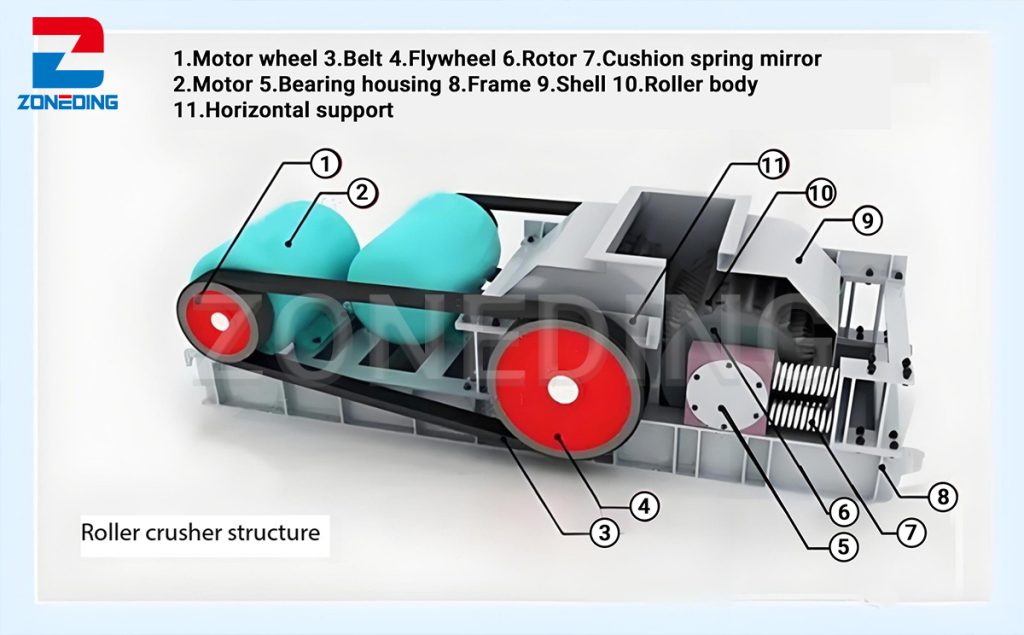

Structure of Toothed Roll Crusher

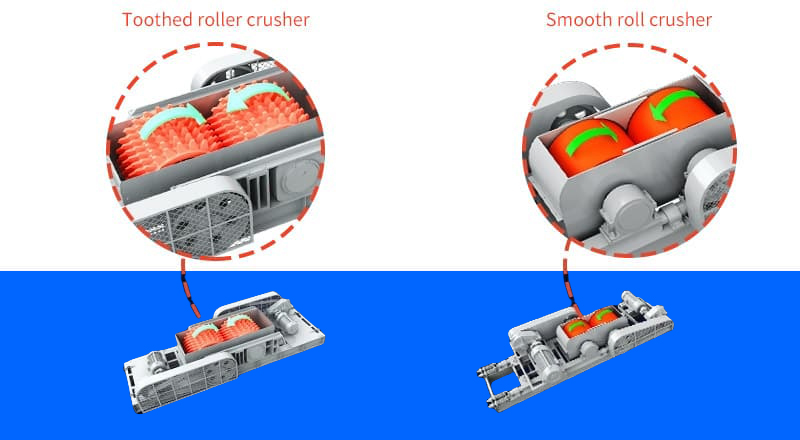

How does a Features of Toothed Roller Crusher work?

Toothed Roll Crusher is mainly composed of two relatively rotating toothed rolls. When the material enters the crushing chamber, it is crushed by the extrusion and shearing effect of the two rolls. By adjusting the gap between the two rolls, the particle size of the crushed material can be controlled. The crushed material is discharged from the bottom of the machine, completing the whole crushing process. This type of crushing has the advantages of large crushing ratio, even particle size, low energy consumption and so on.

Application

Toothed roll crusher is widely used in the following fields:

- Coal industry: it is used to crush coal and gangue to improve the utilization rate and burning efficiency of coal.

- Mining: to crush various ores and provide suitable material size for subsequent beneficiation and smelting.

- Building materials: to produce aggregates used in construction, roads and other projects.

- Metallurgical industry: crushing metal ores to improve smelting efficiency and metal recovery rate.

- Environmental protection and resource recycling: processing construction waste and waste residue, realizing the reuse of resources.

Roll Crusher Several Structural Advantages That Contribute

The counter-roller crusher pulls the material on the roller surface into thecrushing cavity, so that the material is crushed by the stress mainly causedby squeezing, and is taken out of the crushing cavity by the rotating rollerand discharged as the crushed product.

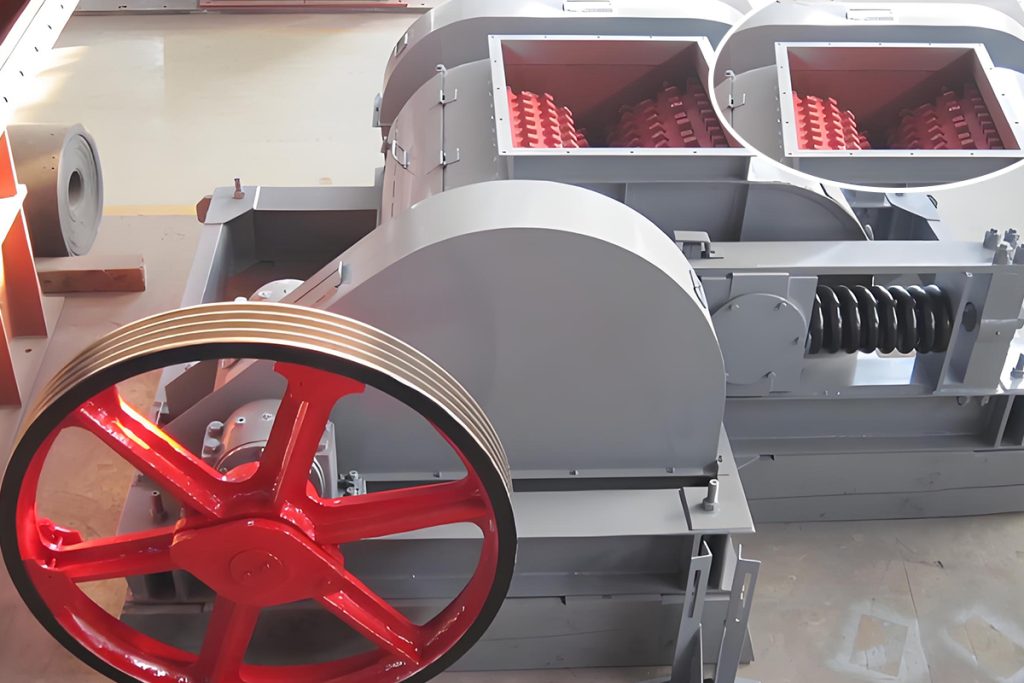

Customer Site

Specification

Toothed Roller Crusher

| Model | Roller diameter(mm) | Roller length(mm) | Max. Feeding Size(mm) | Discharging size(mm) | Output(t/h) | Motor power (kw) | Total weight (t) | Overall dimension (mm) |

| 2PGC600×500 | 600 | 500 | 200-450 | 15-100 | 30-60 | 4P 11×2 | 3.8 | 2450×1800×950 |

| 2PGC600×800 | 600 | 750 | 300-600 | 20-120 | 60-100 | 4P 18.5×2 | 7.2 | 4500×1900×1350 |

| 2PGC800×1000 | 800 | 1000 | 500-800 | 30-150 | 100-160 | 4P 22×2 | 12.6 | 2550×2050×1100 |

| 2PGC1000×1000 | 1000 | 1000 | 700-950 | 30-200 | 150-200 | 6P 45×2 | 18.8 | 2780×4100×1550 |

| 2PGC1200×1200 | 1200 | 1200 | 800-1050 | 30-200 | 180-250 | 6P 55×2 | 29.5 | 2780×3200×1980 |

| 2PGC1500×1200 | 1500 | 1200 | 1000-1150 | 30-200 | 200-300 | 6P 75×2 | 38.6 | 8010×4500×2050 |

Zoneding Machine

Zoneding Machine