Trommel Screen

Trommels remain widely used in some screening operation, including aggregate screening plants and the screening of mill discharge streams. They are also used for wet-scrubbing ores, such as Bauxite, alluvial gold, diamond ores and etc. Usually combined with a gold sluice box to form a one-stop small gold wash plant.

Application of Trommel Screen

A trommel Screen, also known as a rotary drum screen or trommel screener, is a self-cleaning screening machine that separates materials by size.

Compared with vibrating screens, trommel screens can avoid clogging and obtain high output even with dust and sticky materials.

The trommel screen is often used in conjunction with mineral processing equipment such as crushers and ball mills. It can be used in these industries:

- Stone quarry (such as granite): Used for grading large and small stones and separating soil and stone powder

- Sand and gravel field (such as quartz sand): Used for sand and gravel separation

- Coal industry (such as coal gangue): Used for separating lump coal and coal powder and washing coal

- Chemical and mineral processing industries: Used for grading large and small lumps and separating powdery materials

Working Principle Of Portable Trommel Screen

Trommels are installed on a small angle to the horizontal or use a series of internal baffles to transport material along with the cylinder.

When the feeding material enters the roller trommel, due to the tilt and rotation of the trommel, the material on the screen surface is turned and rolled, so that the qualified material (under-screen product) is discharged through the outlet at the bottom of the rear end of the roller, and the unqualified material (upper-screen product) is discharged through the discharge port at the rear of the trommel.

Advantages Of Gold Portable Trommel Screen

- The screening efficiency is high, the screen holes are not easily blocked, and the operation is smooth.

- Simple structure and easy maintenance.

- The portable trommel screen using special screens, high screening efficiency and longer service life can be achieved.

- During the operation of the equipment, the noise generated by the materials and the rotating screen is completely isolated by the sealed dust cover, which eliminates the flying dust during the screening process and provides an excellent operating environment; the noise cannot be transmitted to the outside of the equipment, thereby reducing the equipment noise.

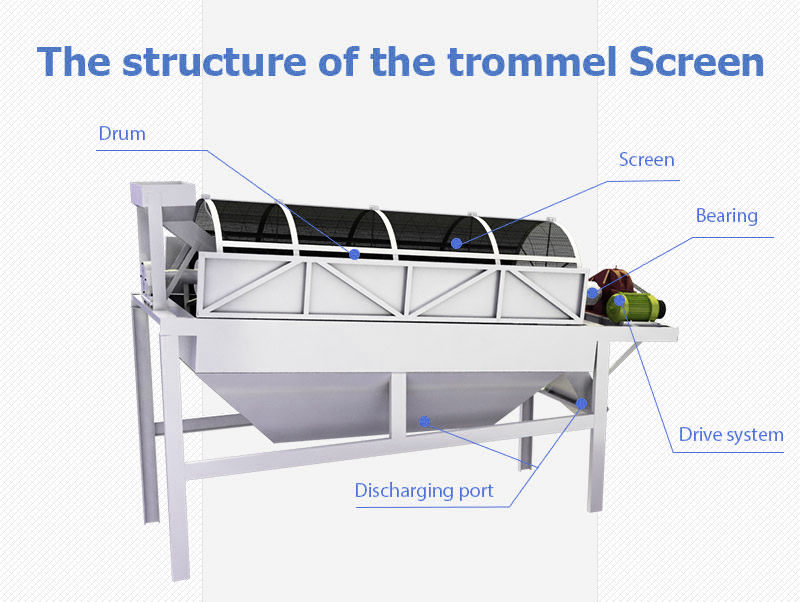

The structure of Trommel Screen

The trommel screen is larger and is a cylinder with holes installed on the frame at an angle. The inclination angle is between 5–30°, close to 30° for light and fine materials, less than 20° for heavier materials, and can be reduced to 5-10° under special circumstances.

Customer site

Specification

Trommel Screen

| Model | Screen Size(mm) | Feeding Size(mm) | Drum Dia (mm) | Drum length (mm) | Process Capacity(t/h) | Motor Power(kw) |

| GT0513 | ≤20 | ≤80 | 500 | 1300 | 1-5 | 3 |

| GT0813 | ≤20 | ≤80 | 800 | 1300 | 5-10 | 4 |

| GT1015 | ≤20 | ≤80 | 1000 | 1500 | 10-15 | 5 |

| GT1020 | ≤25 | ≤80 | 1000 | 2000 | 15-20 | 5.5 |

| GT1225 | ≤25 | ≤100 | 1200 | 2500 | 20-50 | 7.5 |

| GT1530 | ≤25 | ≤100 | 1500 | 3000 | 40-70 | 11 |

| GT1545 | ≤25 | ≤100 | 1500 | 4500 | 70-100 | 15 |

| GT1848 | ≤50 | ≤100 | 1800 | 4800 | 100-150 | 22 |

| GT2055 | ≤50 | ≤100 | 2000 | 5500 | 150-200 | 30 |

Zoneding Machine

Zoneding Machine