Vibrating Feeder

The vibrating feeder can evenly feed materials for the crushing equipment in the sand production line, and screen materials roughly. It can also serve materials for belt conveyors, bucket elevator, screening equipment, crushing equipment and grinding machines.

Features of Vibrating Feeder

- Efficient and uniform feeding: the vibrating feeder is driven by vibrating motor, which can produce strong excitation force to ensure that the materials are fed to the next process evenly and continuously, avoiding blockage and material breakage.

- Adjustable amplitude and frequency: the amplitude and frequency of the equipment can be adjusted according to the characteristics of the material and conveying requirements to meet the requirements of different working conditions.

- Energy saving and environmental protection: the optimized vibration system design reduces energy consumption and noise and meets the environmental protection standard.

- Simple structure, easy maintenance: the equipment has a compact structure, occupies little space, is easy to install and maintain, and reduces the operating cost.

- Strong adaptability: it can be applied to different types of materials, including high temperature, humidity, viscosity and other difficult to handle materials.

Vibratory feeder applications

The vibrating feeders carry the block and grainy materials evenly, regularly and continuously into the targeted device in the process of production. In the sandstone product line, it can not only evenly feed the materials, but screen it as well.

It is widely used in the fields of metallurgical, coal, mineral processing, building materials, chemical engineering, grinding, etc.

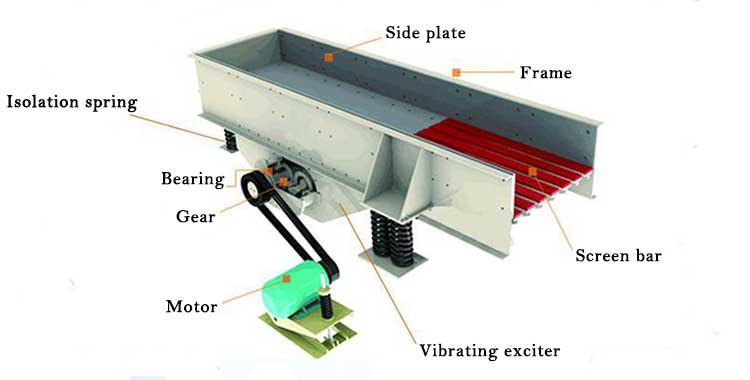

Vibrating feeder structure

How does a Features of Vibrating Feeder work?

Vibrating feeder is mainly composed of vibrating motor, exciter, spring, trough body and other components. When the vibrating motor is started, a periodic excitation force is generated by the exciter, which makes the trough body reciprocate under a certain inclination angle. This vibration effect makes the material in the trough body to produce sliding and throwing movement, so as to move forward along the trough body, to realize uniform and continuous feeding. At the same time, the spring and vibration isolation device can effectively reduce the impact of vibration on the infrastructure to ensure the stable operation of the equipment.

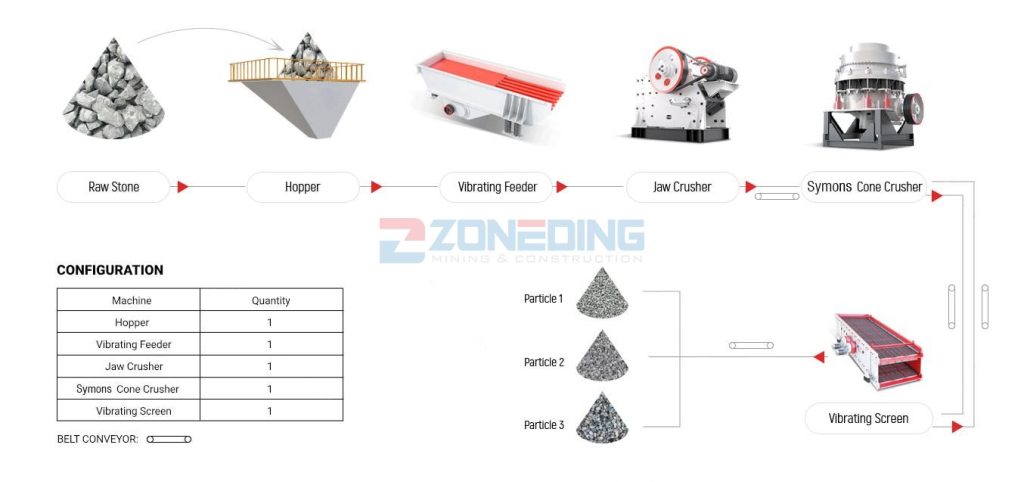

Vibrating feeder process

Customer Site

Specification

Vibrating Feeder

| Model | Max.Feeding Size(mm) | Processing Capacity(t/h) | MotorPower (kw) | Obliquityof materialtrough(°) | Troughsize (mm) | Dimensions (mm) |

| GZD-650×2300 | 300 | 80-100 | 1.2×2 | 10-20 | 650×2300 | 2300×1360×780 |

| GZD-750×2500 | 350 | 100-130 | 1.5×2 | 10-20 | 750×2500 | 2500×1460×780 |

| GZD-850×3000 | 400 | 120-150 | 3×2 | 10-20 | 850×3000 | 3110×1800×1600 |

| GZD-1000×3600 | 500 | 150-200 | 3.7×2 | 10-20 | 1000×3600 | 3850×1950×1630 |

| GZD-1100×3600 | 580 | 240-300 | 3.7×2 | 10-20 | 1100×3600 | 3600×2050×1660 |

| GZD-1300×3600 | 650 | 450-600 | 7.5×2 | 10-20 | 1300×3600 | 3900×2350×1750 |

| GZD-1500×3600 | 1050 | 450-1000 | 7.5×2 | 10-20 | 1500×3600 | 3900×2000×1750 |

| GZD-2000×3600 | 1200 | 550-1000 | 10×2 | 10-20 | 2000×3600 | 3600×2000×1750 |

| GZD-2500×5000 | 1500 | 650-1500 | 18×2 | 10-20 | 2500×5000 | 5000×2500×1800 |

| ZSW-380×95 | 500 | 100-180 | 11 | 0-10 | 3800×960 | 3920×1640×1320 |

| ZSW-490×110 | 630 | 150-400 | 15 | 0-10 | 4900×1100 | 4980×1830×1320 |

| ZSW-490×130 | 750 | 400-700 | 22 | 0-10 | 4900×1300 | 4980×2580×2083 |

| ZSW-600×130 | 750 | 400-700 | 22 | 0-10 | 6000×1300 | 6082×2580×2083 |

| ZSW-600×150 | 800 | 500-900 | 30 | 0-10 | 6000×1300 | 6086×2662×1912 |

| ZSW-600×180 | 900 | 700-1300 | 45 | 0-10 | 6000×1500 | 6310×3262×2230 |

| ZSW-600×200 | 1200 | 800-1500 | 55 | 0-10 | 6000×2000 | 6310×3462×2230 |

Durable Machinery

Durable Machinery