Wood Chips Dryer

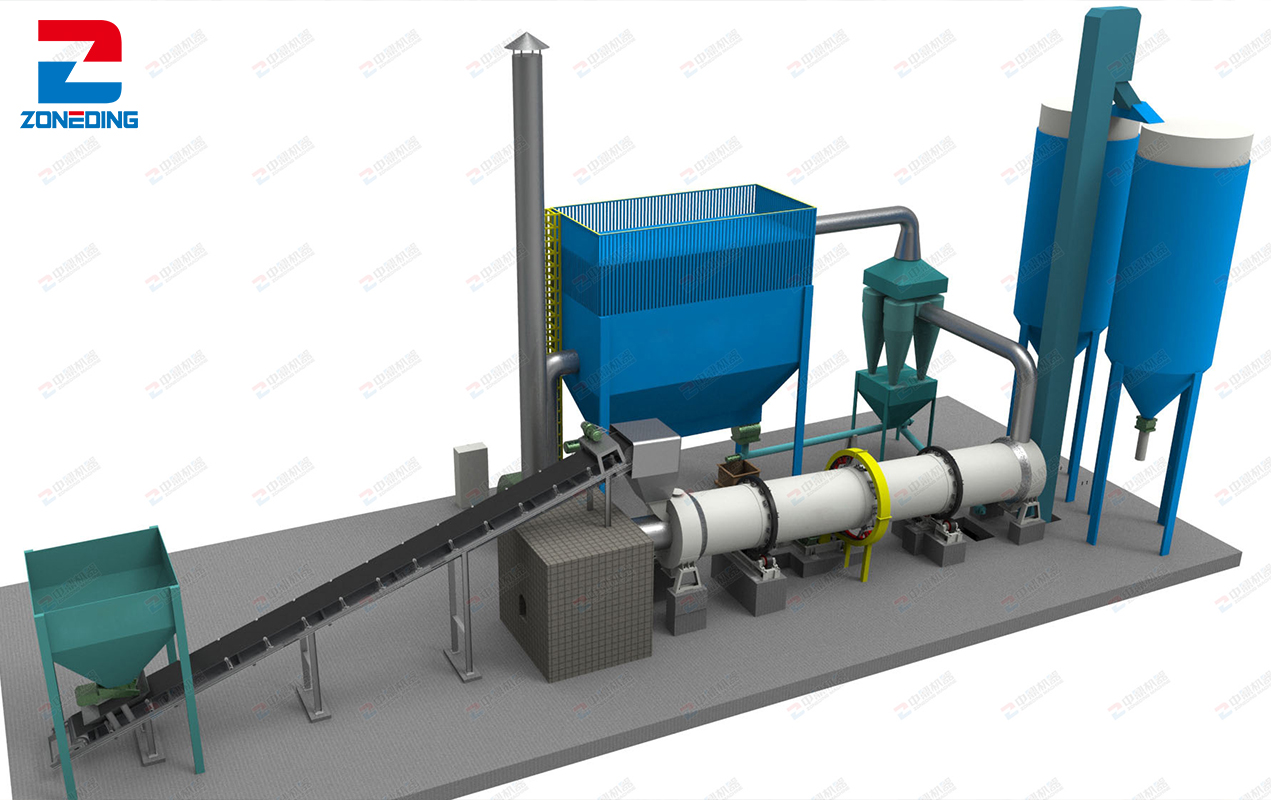

Wood chips dryer is the mainstream equipment in the production of wood pellets and other biomass pellets, and it has been widely used at home and abroad in recent years. The wood chips drying machine adopts high temperature and rapid drying process. The rotary dryer is equipped with biomass fuel hot air stove, and it has a high degree of automation and good drying product quality. The drying system is equipped with safety fire protection devices and hot air waste heat utilization devices, which ensure large output, low cost and reliable production.

Application of Wood Chips Dryer

Wood chip dryer is widely used for drying various biomass materials, like wood chips, sawdust, shavings, bamboo chips, straw (barley straw, oat straw, wheat straw, rye straw, sorghum straw, corn straw), as well as potato vines and bean stalks.

Advantage of Woodchips Dryer

1.The discharge temperature is low, which ensures a long service life of the dust removal equipment and can be continuously produced for the next process.

2.The new combined material lifting device is adopted to adjust the required final moisture according to user requirements.

3.Simple structure, small floor area and easy construction and maintenance.

4.Equipped with new type of energy-saving hot-blast stove, which is highly energy-efficient, thermally controllable, and simple to operate, reducing coal consumption by as much as 60%.

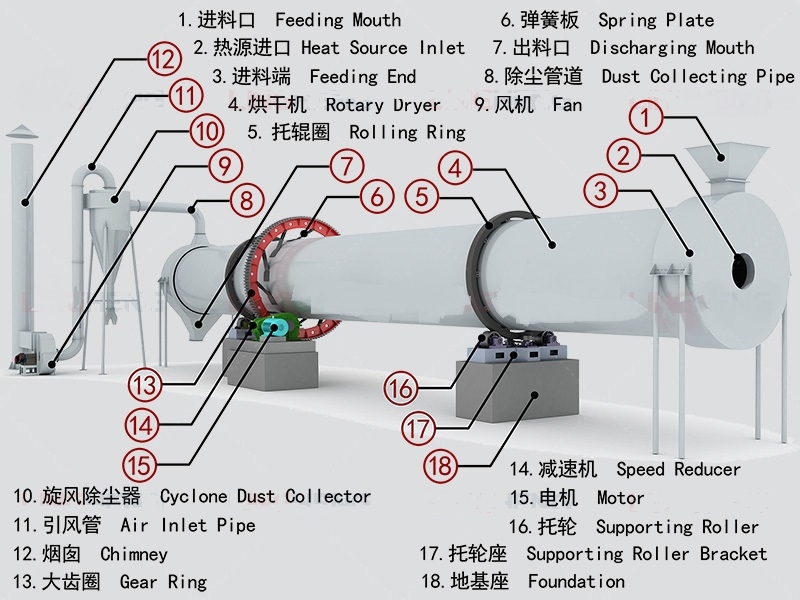

Working Principle of Wood Chip Dryer

The wood chip drying systems feature single and multi-pass technology that moves material (wood chips/sawdust) through the drum in an air stream created by the dryer-induced-draft fan. Multiple passes are mechanically interlocked to rotate at the same speed. As the drum rotates, the product is repeatedly showered into the rotary wood chip dryer’s hot air.

Customer Site

Specification

Drum Dryer

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Durable Machinery

Durable Machinery